Adhesive lining market trends in 2025: Lightweight design and sustainable production

2025-06-12

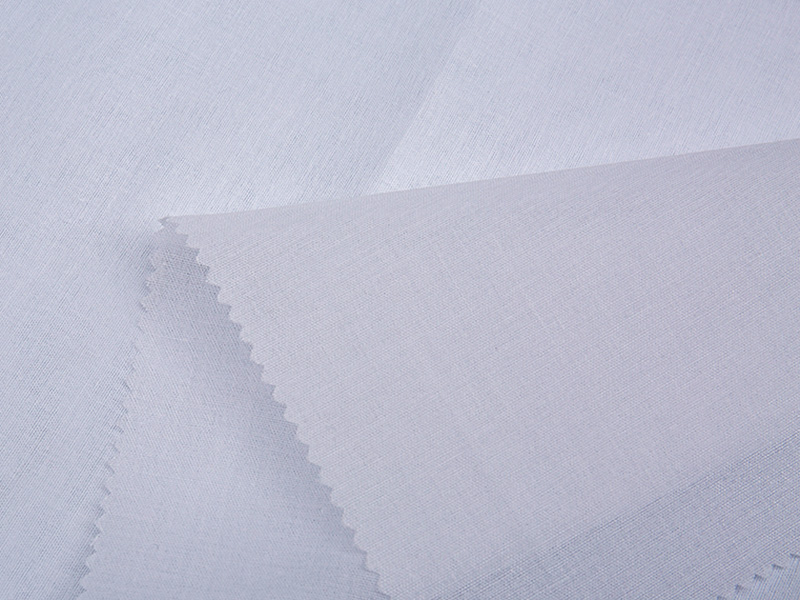

At a time when the textile industry is constantly changing, Adhesive Interlining Fabric is undergoing a profound change in its market trend as a key auxiliary material in clothing and other textile manufacturing. In 2025, lightweight design and sustainable production have become the two core development directions in the field of adhesive lining. This not only conforms to the dual demands of the terminal market for product performance and environmental protection, but also brings new opportunities and challenges to enterprises in the industry.

Lightweight design: Improve product performance and user experience

As consumers' pursuit of clothing comfort and portability is increasing, lightweight has become an important goal of adhesive lining design. The lightweight Adhesive Interlining Fabric can reduce the weight of the clothing without affecting the overall shape and function of the clothing, making the wearer more comfortable to move. For example, in outdoor sports clothing, lightweight adhesive lining can reduce the burden on clothing, improve wear comfort, and meet consumers' requirements for clothing flexibility during running, mountaineering and other activities.

From a technical perspective, the lightweighting of Adhesive Interlining Fabric is mainly achieved through material innovation and structural optimization. On the one hand, new fiber materials are constantly emerging, such as high-performance microfibers, nanofibers, etc. These materials have excellent strength and toughness, and can effectively reduce their weight while ensuring the necessary properties of the lining cloth. On the other hand, in the production process, by improving the weaving or nonwoven technology, a more reasonable inner structure of the lining cloth is built, unnecessary material use is reduced, and lightweight is further achieved. For example, the new knitted structure is adopted to enhance the elasticity of the lining fabric while reducing material accumulation and weight. In addition, some advanced coating technologies can also achieve good bonding effect under extremely thin coating thickness, avoiding increasing the weight of the liner due to heavy coatings.

Sustainable production: Respond to environmental protection calls and practice social responsibility

Against the backdrop of increasing global environmental awareness, sustainable production has become an irreversible trend in the adhesive lining market. Consumers, brands and regulatory authorities have put forward higher requirements on the environmental protection properties of textile products. Adhesive Interlining Fabric’s sustainable production covers all aspects of raw material selection, production process, and product life cycle.

In terms of raw materials, bio-based, recyclable or recycled materials gradually replace traditional unsustainable raw materials. For example, a biodegradable bonded lining developed based on plant fibers can be decomposed in the natural environment after completing the use cycle, reducing long-term pollution to the environment. At the same time, recycled fibers made of recycled plastic bottles, waste textiles, etc. are used for bonded lining production, which not only realizes the recycling of resources, but also greatly reduces the mining and consumption of new resources. During the production process, the company is committed to energy conservation and emission reduction and adopts clean production technology. For example, optimize the coating process to reduce the amount of glue used, or use water-based, solvent-free glue to replace traditional organic solvent-based glues, reduce emissions of volatile organic compounds (VOCs) and reduce pollution to the atmospheric environment. Improve production equipment and processes, improve energy utilization efficiency, and reduce energy consumption and greenhouse gas emissions.

Lightweight and sustainable synergistic development

It is worth noting that lightweight design and sustainable production do not exist in isolation in the field of Adhesive Interlining Fabric, but are a relationship of mutual promotion and coordinated development. Lightweight material selection and structural design often help reduce resource consumption and energy use, thus fitting the concept of sustainable production. For example, although the R&D cost of using new lightweight high-strength fibers may be high, due to the reduced usage, the overall investment in resources and energy will be reduced from the perspective of the entire product life cycle. The pursuit of cleaning technology and recycling in the sustainable production process also provides more technical support and material selection for lightweight design. For example, some recyclable materials have good lightweight properties after special treatment, which meets the market's dual demand for product performance and environmental protection.

Looking ahead to 2025 and in the future, the adhesive lining market will continue to innovate and develop driven by lightweight design and sustainable production. Enterprises need to increase investment in R&D, actively explore new technologies and new materials to adapt to market changes and meet the ever-elevated consumption needs. At the same time, the industry also needs to strengthen the formulation and guidance of standardization, promote the entire adhesive lining industry to move towards a greener, more efficient and sustainable direction, and contribute to the sustainable development of the textile industry.

Contact Us for More Details

Don't hesitate to contact when you need us!

English

English  中文简体

中文简体