High Elasticity Interlining for Stretch Fabrics: Improve Fit, Comfort, and Durability

2025-10-14

Understanding High Elasticity Interlining

High elasticity interlining is a specialized material engineered to work harmoniously with stretch fabrics, providing structural support while maintaining the fabric's inherent flexibility. Unlike traditional interlinings that can restrict movement, high elasticity variants move with the garment, ensuring optimal performance in applications requiring dynamic motion. This innovative component has become indispensable in modern apparel manufacturing, particularly for sportswear, formal stretch garments, and adaptive clothing where both form and function are paramount.

The fundamental purpose of high elasticity interlining is to provide controlled reinforcement to stretch fabrics without compromising their elastic properties. When integrated correctly, it helps maintain the garment's shape over time, prevents distortion at stress points like collars and cuffs, and enhances overall durability. The interlining achieves this through its unique composition and construction, typically utilizing elastic polymers, specialized weaving techniques, or advanced bonding technologies that allow for multidirectional stretch recovery.

How High Elasticity Interlining Differs from Standard Interlining

Traditional interlinings and high elasticity interlinings serve fundamentally different purposes and exhibit distinct performance characteristics. Standard interlinings are designed primarily for structural stabilization in woven fabrics with little to no stretch, while high elasticity interlinings are specifically engineered for knit and stretch-woven fabrics that require movement accommodation.

The key differences can be summarized as follows:

| Characteristic | Standard Interlining | High Elasticity Interlining |

|---|---|---|

| Stretch Recovery | Minimal to none (0-5%) | Excellent (30-100%+ depending on type) |

| Primary Application | Structured garments, suit jackets, formal wear | Activewear, stretch formalwear, intimate apparel |

| Compatibility | Woven, non-stretch fabrics | Knit and stretch woven fabrics |

| Flexibility | Rigid support | Flexible support with movement |

| Weight | Generally heavier | Lighter weight options available |

The Essential Role of High Elasticity Interlining in Modern Garments

High elasticity interlining serves multiple critical functions in contemporary apparel that extend far beyond simple reinforcement. Its unique properties make it invaluable for achieving specific performance characteristics and aesthetic qualities in stretch fabric applications. Understanding these roles helps designers and manufacturers make informed decisions about when and how to incorporate this specialized material into their products.

Structural Integrity Without Compromise

One of the primary challenges when working with stretch fabrics is maintaining structural integrity in specific garment areas while preserving overall flexibility. High elasticity interlining addresses this challenge by providing targeted support where needed—such as collars, cuffs, plackets, and waistbands—without creating uncomfortable rigid zones. This selective reinforcement prevents these high-stress areas from stretching out of shape over time while allowing the garment to move naturally with the body.

Enhanced Comfort and Wearability

Comfort is paramount in modern apparel, and high elasticity interlining contributes significantly to this aspect. Unlike stiff traditional interlinings that can create pressure points and restrict movement, high elasticity variants move synchronously with both the fabric and the body. This synchronized movement reduces friction, eliminates binding, and creates a second-skin feel that enhances wearability throughout the day. The result is clothing that supports rather than constrains, making it ideal for extended wear in both active and sedentary scenarios.

Choosing the Right High Elasticity Interlining for Your Project

Selecting the appropriate high elasticity interlining requires careful consideration of multiple factors to ensure optimal performance and compatibility with your specific fabric and application. The wrong choice can lead to issues such as reduced stretch recovery, bubbling, delamination, or an unnatural hand feel. By understanding the key selection criteria, you can make informed decisions that enhance your final product rather than compromise it.

Weight and Hand Considerations

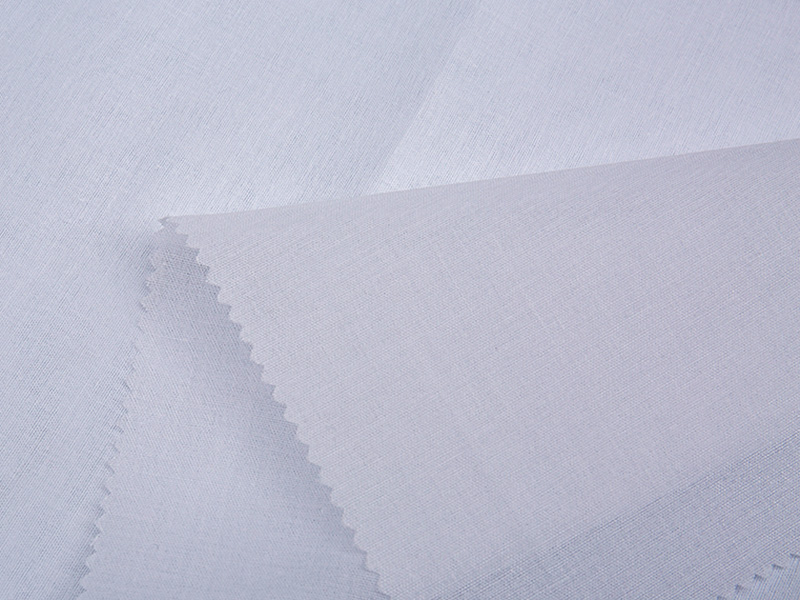

The weight and hand (drape and feel) of high elasticity interlining must complement rather than overwhelm the base fabric. Lightweight, delicate stretch fabrics require equally lightweight interlinings that provide support without adding substantial bulk or stiffness. Heavier stretch fabrics can accommodate more substantial interlinings that offer greater structural reinforcement. The ideal interlining will preserve the natural drape and movement of the fabric while providing the necessary support for the specific application.

Stretch Direction and Percentage Matching

Perhaps the most critical technical consideration is ensuring the interlining's stretch properties match those of your base fabric. High elasticity interlining for two-way stretch fabrics is specifically engineered for fabrics that stretch primarily in one direction (either warp or weft), while high elasticity interlining for four-way stretch fabrics is designed for materials that stretch in both directions. Using a two-way interlining on a four-way stretch fabric will create resistance in one direction, resulting in discomfort and potential garment distortion.

Stretch Direction Compatibility Guide

Understanding stretch direction compatibility is essential for achieving optimal garment performance. The following comparison illustrates the key considerations when matching interlining to fabric stretch properties:

| Stretch Type | Best For Fabric Types | Interlining Requirements | Common Applications |

|---|---|---|---|

| Two-Way Stretch | Stretch wovens, some knits with primary stretch in one direction | Stretch primarily in one direction with minimal cross-direction stretch | Dress shirts, tailored pants, some structured jackets |

| Four-Way Stretch | Modern performance knits, jersey, spandex blends | Equal stretch in both directions with excellent recovery | Activewear, compression garments, form-fitting apparel |

| Bias Stretch | Specialty wovens, certain draping applications | Diagonal stretch properties matching fabric bias | Bias-cut garments, special draping effects |

Application Methods for Optimal Results

The application method used to attach high elasticity interlining to your base fabric significantly impacts the final garment's performance, durability, and aesthetic qualities. Different methods offer distinct advantages and limitations, making certain techniques more suitable for specific fabric types, production scales, and performance requirements. Understanding these application options enables manufacturers to select the most appropriate method for their particular needs.

Fusing Techniques for Stretch Fabrics

Fusing, or heat-activated bonding, is a popular application method for high elasticity interlining, but it requires specialized equipment and precise temperature control to achieve optimal results without damaging the stretch properties of the base fabric. The fusing process involves applying heat and pressure to activate adhesive coatings on the interlining, creating a permanent bond with the base fabric. However, standard fusing techniques used for traditional interlinings often prove problematic for stretch fabrics, as excessive heat or pressure can degrade elastic fibers and impair recovery.

Best Practices for Fusing High Elasticity Interlining

Successful fusing of high elasticity interlining requires adherence to specific protocols to preserve the stretch characteristics of both materials. The following guidelines help ensure optimal results:

- Always conduct preliminary tests with fabric and interlining swatches to determine ideal temperature, pressure, and timing settings.

- Use fusing machines with precise temperature control capabilities, as even slight variations can affect bond quality and stretch retention.

- Employ Teflon or silicone sheets during fusing to prevent adhesive transfer to machine plates, which can create inconsistent bonding.

- Allow fused components to cool completely before handling to ensure the bond fully sets without distortion.

- Check stretch recovery after fusing by stretching the fused section and verifying it returns to its original dimensions without delamination.

Sewing and Stitching Applications

For certain applications and fabric types, sewing high elasticity interlining to the base fabric provides advantages over fusing, particularly when maximum stretch preservation is required. This method involves stitching the interlining to specific garment sections before construction, either through traditional sewing or specialized techniques like cover stitching. While more labor-intensive than fusing, sewing often yields superior stretch retention since it avoids the heat exposure that can compromise elastic fibers.

Specialized Applications and Considerations

Beyond general apparel applications, high elasticity interlining serves specialized purposes in specific garment types and scenarios. Understanding these niche applications helps manufacturers and designers leverage the full potential of this versatile material to solve unique challenges in stretch fabric construction.

High Elasticity Interlining for Formal Wear

The integration of stretch fabrics into formal wear has created new opportunities for comfort and fit in traditionally rigid garment categories. High elasticity interlining for formal wear enables the creation of structured elements like collars, cuffs, and front plackets that maintain their shape while moving comfortably with the body. This specialized interlining category addresses the unique requirements of formal garments, where appearance standards remain high despite the incorporation of stretch materials.

When selecting high elasticity interlining for formal applications, several factors demand particular attention. The interlining must provide sufficient structure to maintain the crisp appearance expected in formal contexts while offering enough flexibility to accommodate movement. Additionally, formal wear often utilizes finer, more delicate fabrics that require interlinings with appropriate weight and hand. The interlining should also withstand professional cleaning processes common to formal garments without degrading or delaminating.

Washable High Elasticity Interlining Options

Durability through repeated laundering represents a critical consideration for many stretch fabric applications, particularly in categories like sportswear, children's clothing, and everyday garments that undergo frequent washing. Washable high elasticity interlining is specifically engineered to maintain its bonding strength, stretch recovery, and structural integrity through multiple wash cycles. This specialized category addresses the unique challenges posed by modern washing conditions, including aggressive detergents, varying water temperatures, and mechanical agitation.

Performance Comparison of Washable Interlining Types

Not all washable high elasticity interlinings perform equally under different laundering conditions. The following comparison highlights how different types withstand various washing scenarios:

| Interlining Type | Machine Wash Performance | Hot Water Resistance | Chemical Cleaner Compatibility | Long-Term Durability |

|---|---|---|---|---|

| Standard Washable | Good up to 40°C / 104°F | Moderate - may weaken above 60°C / 140°F | Limited compatibility with harsh chemicals | 20-30 washes with minimal degradation |

| Premium Washable | Excellent up to 60°C / 140°F | Good resistance to 95°C / 203°F | Compatible with most commercial detergents | 50+ washes with minimal degradation |

| Industrial Grade | Excellent at all temperatures | Superior resistance to boiling water | Compatible with industrial cleaning chemicals | 100+ washes with minimal degradation |

Breathable High Elasticity Interlining for Activewear

Activewear represents one of the most demanding applications for high elasticity interlining, requiring not only excellent stretch recovery but also moisture management and breathability properties. Breathable high elasticity interlining for activewear addresses these specialized needs through unique constructions that allow air circulation and moisture vapor transmission while providing structural support. This category has evolved significantly to meet the performance expectations of modern athletes and fitness enthusiasts who require garments that support intense physical activity without compromising comfort.

The development of breathable high elasticity interlining involves sophisticated engineering approaches that create microscopic pathways for air and moisture while maintaining the interlining's structural integrity. These specialized interlinings typically feature porous constructions, moisture-wicking treatments, and enhanced drying capabilities that work in concert with technical base fabrics. When selecting breathable interlining for activewear applications, manufacturers must consider factors such as moisture vapor transmission rate (MVTR), air permeability, drying time, and how these properties interact with the base fabric's performance characteristics.

Troubleshooting Common Issues with High Elasticity Interlining

Despite technological advancements, manufacturers may encounter specific challenges when working with high elasticity interlining. Understanding these potential issues, their underlying causes, and appropriate solutions helps minimize production problems and ensures consistent quality in finished garments. The following section addresses common complications and provides practical guidance for resolution and prevention.

Delamination and Bond Failure

Delamination, where the interlining separates from the base fabric, represents one of the most frequent issues in stretch fabric applications. This problem typically stems from incompatible adhesive systems, improper fusing parameters, or mismatched stretch properties between the interlining and base fabric. Addressing delamination requires systematic investigation to identify the root cause and implement appropriate corrective measures.

Preventing Delamination in Production

Proactive measures during the production planning phase can significantly reduce the incidence of delamination in finished garments. The following strategies help prevent bond failure:

- Conduct comprehensive compatibility testing before full-scale production, assessing bond strength both initially and after simulated aging.

- Ensure fusing equipment is properly calibrated and maintained, with regular checks of temperature uniformity across pressing surfaces.

- Match the adhesive type to the fabric composition, considering factors like fiber content, surface texture, and finishing treatments.

- Implement strict quality control checks at multiple production stages, including peel tests on fused components.

- Consider the garment's entire lifecycle, including cleaning methods, when selecting interlining adhesive systems.

Stretch Recovery Degradation

Another common challenge involves the gradual loss of stretch recovery in interlined garment sections, resulting in sagging, bagging, or permanent deformation in areas like collars and cuffs. This issue typically develops over time with wear and cleaning, though improper processing during manufacturing can accelerate the degradation. Addressing stretch recovery problems requires understanding the multiple factors that contribute to elastic performance deterioration.

Future Trends in High Elasticity Interlining Technology

The field of high elasticity interlining continues to evolve rapidly, driven by advancements in material science, changing consumer expectations, and emerging applications in smart textiles and sustainable apparel. Understanding these developing trends helps manufacturers and designers anticipate future opportunities and challenges in stretch fabric applications.

Sustainability and Eco-Friendly Innovations

Environmental considerations increasingly influence interlining development, with growing demand for sustainable options that maintain performance standards while reducing ecological impact. Recent innovations in this space include bio-based elastic polymers, recycled content interlinings, and biodegradable options that break down at end-of-life without releasing harmful substances. These sustainable alternatives aim to address concerns about microplastic pollution, resource depletion, and chemical usage throughout the product lifecycle.

Integration with Smart Textile Systems

The convergence of high elasticity interlining with smart textile technologies represents an exciting frontier in functional apparel. Researchers and manufacturers are developing interlinings that incorporate conductive elements, sensing capabilities, and responsive properties while maintaining essential stretch characteristics. These advanced materials could enable garments that monitor physiological metrics, adjust their properties based on environmental conditions, or interface seamlessly with electronic devices—all without compromising comfort or mobility.

As high elasticity interlining technology continues to advance, we can expect further specialization for specific applications, improved sustainability profiles, and enhanced integration with digital design and manufacturing processes. These developments will expand the creative and functional possibilities for designers working with stretch fabrics while addressing practical concerns around durability, comfort, and production efficiency. The future of high elasticity interlining lies in increasingly sophisticated solutions that bridge the gap between structural requirements and the dynamic nature of modern apparel.

Contact Us for More Details

Don't hesitate to contact when you need us!

English

English  中文简体

中文简体