The Engineering of Soft Lightweight Interlining Fabric: A Technical Guide for High-End Garment Construction

2026-02-17

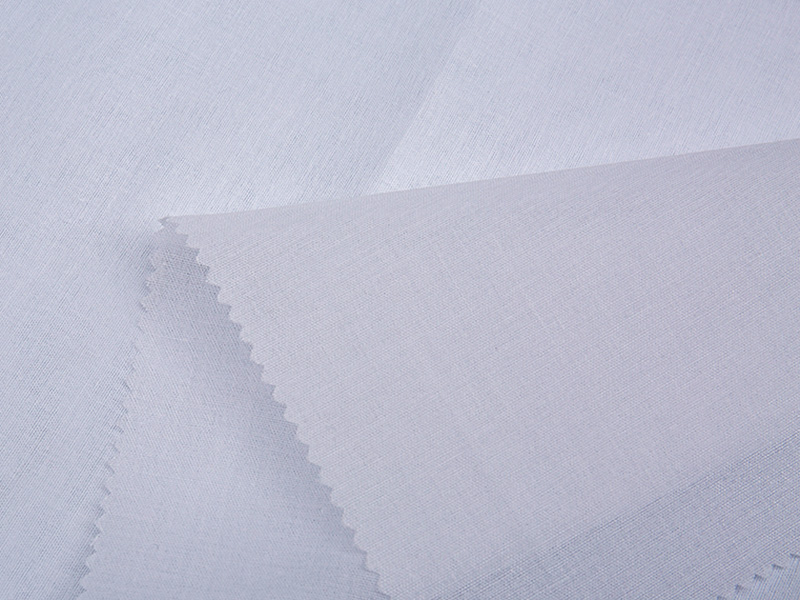

In the realm of high-end tailoring and garment engineering, the "skeleton" of a piece is often invisible but dictates the final silhouette, drape, and durability. The soft l,ightweight interlining fabric has evolved from basic stiffening agents to highly engineered textile composites designed to provide structural support without compromising the natural hand-feel of the outer shell. Modern garment manufacturing requires a deep understanding of adhesive polymers, base cloth construction, and thermal bonding parameters to ensure seamless integration between the interlining and face fabric. This guide explores the technical specifications and decision-making matrices for utilizing high-quality fusible interlining in contemporary fashion.

1. Structural Analysis: Base Cloth Composition and Weave Density

The performance of a soft, lightweight interlining fabric begins with its base substrate. Unlike heavy-tailoring interlinings, lightweight variants utilize low-denier yarns, typically ranging from 15D to 30D. The choice between woven and non-woven structures significantly impacts the garment's recovery and multidirectional stretch. For instance, a woven interlining vs non-woven interlining for clothing comparison reveals that woven structures offer superior bias stability and "memory," making them ideal for areas requiring precise shaping, such as collars and cuffs in fine silk blouses. Non-woven variants, produced through thermal or chemical bonding, provide a more isotropic support structure suitable for fast-fashion or less structured casual wear.

| Property | Woven Lightweight Interlining | Non-Woven Lightweight Interlining |

| Drape Fluidity | High (Follows fabric grain) | Moderate (More rigid) |

| Tensile Strength | Excellent (Directional) | Moderate (Uniform) |

| Application | Bespoke tailoring, silk, fine wool | Casual wear, small crafts, pocketing |

2. Adhesive Technology: Double-Dot vs. Single-Dot Coating

To achieve an "sft" andle, the distribution of the thermoplastic adhesive is paramount. Engineers often debate the merits of different coating methods. A double-dotted interlining analysis shows that the double-dot method provides a superior barrier against "strike-back" (adhesive leaking through to the face fabric) while maintaining a flexible bond. This is achieved by using a base layer of high-viscosity resin and a top layer of low-melt adhesive. For the best interlining for silk and chiffon, the double-dot coating is non-negotiable, as it preserves the translucency and airy nature of the delicate fibers while preventing the "orange peel" effect during thermal processing.

3. Thermal Bonding Parameters and Peel Strength

The integration of soft light-weight interlining fabric requires precise control over temperature, pressure, and time. If the heat is too low, the bond strength (peel strength) will be insufficient, leading to delamination after laundering. Conversely, excessive heat can damage fine fibers. When evaluating how to choose interlining for sheer fabrics, engineers look at the "oftening point" of the adhesive—typically Polyamide (PA) or High-Density Polyethylene (HDPE). A critical factor in quality control is the post-wash shrinkage rate; a high-quality fusible interlining should have a shrinkage rate compatible with the face fabric (usually less than 0.5%) to prevent puckering at the seams.

Comparison: Adhesive Polymer Performance

Polyamide adhesives are preferred for dry-cleanable garments, whereas Polyester (PES) or HDPE are utilized for items requiring high-temperature laundering.

| Polymer Type | Bonding Temperature | Laundering Resistance |

| Polyamide (PA) | 120°C - 140°C | Excellent (Dry Clean / 40°C Wash) |

| Polyester (PES) | 130°C - 150°C | Excellent (60°C Wash) |

| Low-Melt PA | 100°C - 115°C | Moderate (Delicate cycle only) |

4. Managing the "ad-Feel" in Delicate Construction

The ultimate goal of using fusible interlining for delicate fabrics is to remain imperceptible to the wearer. The weight of soft interlining for summer clothes usually falls between 15g/m² and 35g/m². At the engineer level, this is balanced with the "stiffness coefficient."" Too much stiffness creates a synthetic appearance, while too little fails to support the garment's design. Utilizing a breathable soft interlining for activewear is also a rising trend, where micro-perforated non-wovens allow for moisture vapor transmission without compromising the structural integrity of high-stretch synthetic blends.

Key Technical Advantages of Professional Interlining:

- Strike-through prevention: Advanced resin layers ensure adhesive remains in the interface.

- Crease Resistance: High-tenacity base yarns prevent permanent fold lines.

- Compatibility: Engineered to bond with silicone-treated or DWR-coated fabrics.

- Eco-Friendly: Formulated without formaldehyde or heavy metal catalysts.

5. Conclusion: Precision in Selection

Selecting the correct soft light, weight interlining fabric is a blend of textile science and artisanal intuition. By carefully calculating the interlining and face fabric compatibility through test fusions and peel-strength analysis, manufacturers can produce garments that retain their shape and elegance through years of wear and maintenance. As technology advances, the move toward sustainable, bio-based adhesives will further refine the efficiency and environmental footprint of our industry's invisible support systems.

Frequently Asked Questions (FAQ)

1. Why is double dot vs single dot interlining a major factor for thin fabrics?

Double-dot technology creates a ""cushon""between the adhesive and the fabric, preventing the glue from seeping through (strike-back) or making the delicate face fabric feel rough or"papery""

2. Can I use soft lightwe,ight interlining fabric for structured jackets?

Generally, lightweight variants are used for reinforcement in specific areas (like seams or pocket welts) of a structured jacket, but the main body usually requires a medium or heavy-wheavyweightining to hold the sharp tailoring lines.

3. What are the benefits of woven interlining vs non-woven for expensive garments?

Woven interlining behaves more like real fabric; it drapes naturally and has a better "recovery" after being stretched, whereas non-woven can sometimes feel stiff or become distorted over multiple dry-cleaning cycles.

4. How to choose interlining for sheer fabrics like organza?

Choose an ultra-lightweight (15-20g) soft lightweight interlining fabric with a double-dot PA coating and a color that matches the fabric exactly to prevent visual detection.

5. Is high-quality fusible interlining permanent?

Yes, if applied with the correct industrial bonding parameters (heat, time, and pressure). A professional bond should withstand at least 20-50 laundering or dry-cleaning cycles without bubbling or delaminating.

Industry References

- ASTM D2724: Standard Test Methods for Bonded, Fused, and Laminated Apparel Fabrics.

- ISO 6330: Textiles — Domestic washing and drying procedures for testing.

- Textile Institute: "The Technology of Interlinings and Fusing, "4th Edition.

- OEKO-TEX Standard 100: Testing for harmful substances in interlining adhesives.

Contact Us for More Details

Don't hesitate to contact when you need us!

English

English  中文简体

中文简体