The Ultimate Guide to Light-weight Interlining: Types, Benefits, and Applications

2025-11-21

In the world of textiles and garment construction, the unseen hero often lies within the fabric itself. Light-weight interlining is a crucial component that provides structure, shape, and a premium feel without adding bulk. For over two decades, Hetai Textile has been at the forefront of developing and manufacturing high-quality interlining fabrics. Founded in 2002 and based in Jiangsu Province, China, we have grown into a full-spectrum enterprise with integrated weaving, dyeing, and coating workshops. Our commitment to innovation and a comprehensive quality control system ensures we deliver superior products that meet the diverse and evolving needs of the global market. This guide will delve deep into the world of light-weight interlining, exploring its benefits, types, and ideal applications.

Why Choose Light-weight Interlining? Unpacking the Key Benefits

Selecting the right interlining is pivotal for achieving the desired drape, durability, and finish in a garment. Light-weight interlining offers a unique set of advantages that make it indispensable for modern, elegant apparel.

Enhanced Drape and Flexibility

- Superior Drape: Unlike heavier alternatives, light-weight interlining allows fabric to flow and move naturally.

- Maintains Fabric Hand: It preserves the original softness and texture of the face fabric.

- Ideal for Delicate Materials: Perfect for silks, chiffons, and other fine materials that require support without stiffness.

Comfort and Wearability

- Reduced Bulk: It adds structure without the weight, leading to more comfortable garments for the wearer.

- Breathability: Many light-weight interlinings are designed to allow air circulation.

- Seasonless Application: Suitable for garments worn in various climates due to its minimal insulation.

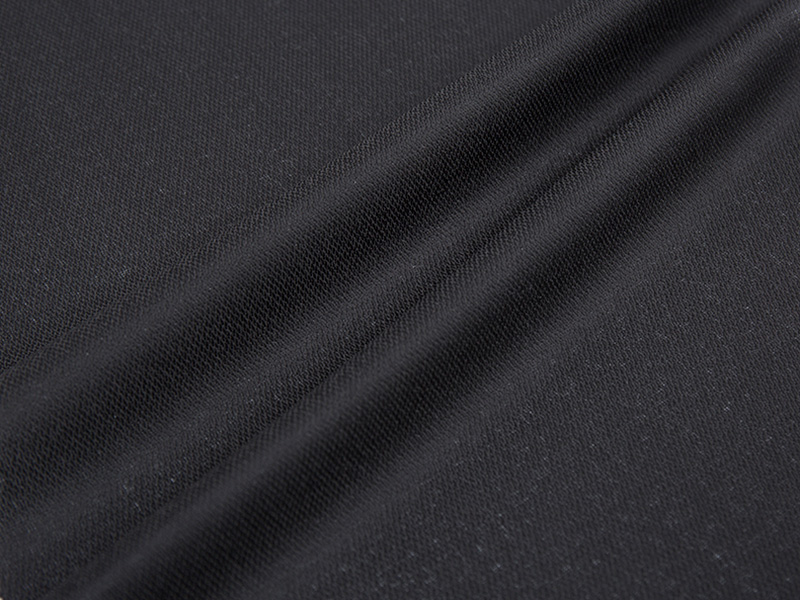

Exploring the Different Types of Light-weight Interlining

Not all light-weight interlinings are created equal. The method of application and fiber content determines its best use. Understanding these differences is key to selecting the perfect fusible for your project.

Woven vs. Non-Woven: A Fundamental Comparison

The primary distinction in interlining construction lies between woven and non-woven materials. Each offers distinct properties that cater to different needs.

| Feature | Woven Interlining | Non-Woven Interlining |

| Structure | Made from yarns interlaced lengthwise and crosswise, mimicking traditional fabrics. | Made from fibers bonded together chemically, thermally, or mechanically. |

| Drape & Hand | Generally offers superior drape and a more natural, fabric-like hand. | Can be more rigid, though modern versions have improved significantly. |

| Durability | Typically more durable and resistant to fraying. | Less durable; can tear more easily. |

| Common Use | Ideal for high-end tailored garments, blazers, and structured dresses. | Often used for appliques, craft projects, and areas requiring temporary stabilization. |

Fusible Interlining Application Methods

Fusible interlinings are the most common type, bonded to the fabric using heat and pressure. The application process is critical for a flawless finish.

- Temperature: Using the correct iron or fusing press temperature is essential to avoid shine or bubbling.

- Pressure: Even pressure ensures a consistent bond across the entire surface.

- Time: The fusing duration must be precise to activate the adhesive completely without damaging the face fabric.

For instance, how to apply fusible light-weight interlining correctly involves a test piece first to calibrate your equipment. This simple step prevents costly mistakes on the final garment.

1. light-weight interlining for dresses

Dresses, from flowing maxi dresses to structured sheaths, benefit immensely from the right interlining.

- Necklines and Collars: Provides crisp definition and prevents sagging.

- Button Plackets: Prevents stretching and distortion around buttonholes.

- Belt Loops and Waistbands: Adds durability to high-stress areas.

- Cuffs and Hems: Creates a clean, finished edge that maintains its shape.

2. light-weight interlining for shirts

The goal for shirts is a polished, professional look that remains comfortable through a full day's wear.

- Collars and Cuffs: The primary application, giving them body and a sharp appearance that withstands repeated washing.

- Plackets: Stabilizes the front buttoning area for a neat, wrinkle-resistant finish.

- Yoke: Adds a subtle structure to the back of the shirt for a better fit.

When comparing light-weight interlining for shirts to heavier options, the key difference is comfort. A light-weight fusible provides the necessary structure without making the collar feel stiff or restrictive against the skin.

3. light-weight fusible interlining types

The world of fusibles is diverse. The main types are defined by their base cloth and adhesive coating.

| Type | Base Material | Key Characteristics | Ideal For |

| Woven Fusible | Cotton, Polyester, or Blends | Excellent drape, strong, durable, breathable. | Shirt collars, tailored jackets, high-end dresses. |

| Non-Woven Fusible | Bonded Fibers | Cost-effective, uniform strength, less fraying. | Crafting, home decor, temporary stabilization. |

| Weft Insertion Fusible | Non-Woven base with woven yarns inserted | Compromise between drape of woven and stability of non-woven. | Skirt hems, lightweight jackets. |

| Knitted Fusible | Knit Fabric | Extremely flexible and stretchy, moves with the fabric. | Jersey garments, knitwear, stretch fabrics. |

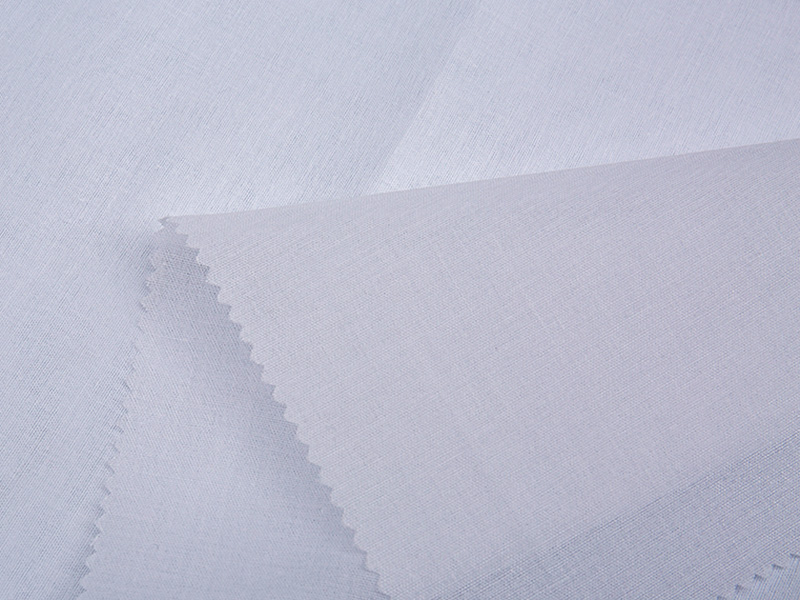

4. best light-weight interlining for delicate fabrics

Delicate fabrics like silk, chiffon, and voile demand an interlining that is equally gentle yet effective.

- Low-Temperature Adhesives: Designed to fuse at lower heat to prevent scorching or melting.

- Soft Hand: The interlining itself must be very soft to not alter the delicate drape of the face fabric.

- Sheer Options: Available in ultra-light weights that are virtually undetectable.

Identifying the best light-weight interlining for delicate fabrics often requires a sample swatch test. At Hetai Textile, our technical team specializes in recommending the perfect match for such sensitive materials, ensuring a flawless result.

5. how to choose light-weight interlining

Making the right choice involves a systematic evaluation of your project's requirements.

- Consider the Face Fabric: Weight, fiber content, and drape are the primary drivers.

- Define the Desired Outcome: Do you need more body, stability, or just a crisp edge?

- Consider the End Use: A garment that will be washed frequently needs a durable fusible that can handle the process.

- Test, Test, Test: Always fuse a sample to check for compatibility, hand, and any potential issues like adhesive strike-through.

Innovation in Light-weight Interlining at Hetai Textile

Staying at the industry's forefront requires continuous investment in research and development. At Hetai Textile, our advanced production lines and dedicated technical team are constantly innovating.

- Eco-Friendly Solutions: Developing interlinings with recycled content and environmentally conscious adhesives.

- Enhanced Performance: Creating interlinings with properties like moisture-wicking or anti-static.

- Precision Engineering: Ensuring consistent weight, adhesion, and shrinkage control across every batch.

Our integrated process—from weaving and dyeing to coating—allows for complete quality control, ensuring that every meter of our light-weight interlining meets the highest standards of performance and reliability.

Frequently Asked Questions (FAQ)

1. What is the main difference between light-weight and medium-weight interlining?

The core difference is the amount of body and structure they impart. Light-weight interlining adds minimal body and is designed to preserve the natural drape of delicate or flowing fabrics. Medium-weight interlining provides more pronounced structure and is typically used for areas like jacket collars or bags that require more rigidity.

2. Can light-weight interlining be washed?

Yes, most modern light-weight interlinings are designed to be washable. However, it is crucial to follow the care instructions for both the interlining and the face fabric. Always test a sample first to ensure the bond remains secure and there is no shrinkage or bubbling after washing.

3. How do I prevent my iron from sticking to the fusible interlining?

Always use a pressing cloth between your iron and the fusible interlining. This thin, heat-resistant fabric layer protects both your iron's soleplate and the surface of your project from direct contact with the activated adhesive.

4. Is light-weight interlining suitable for stretch fabrics?

For stretch fabrics, a specialized knitted interlining is the best choice. Unlike standard woven or non-woven interlinings, knitted fusibles are designed to stretch with the fabric, preventing popped seams and a restrictive feel.

5. What makes Hetai Textile's approach to interlining unique?

Founded in 2002, Hetai Textile operates as a full-spectrum enterprise with complete control over the entire production process, from weaving and dyeing to coating. This vertical integration, supported by a top-tier technical team and a rigorous quality control system, allows us to ensure consistent, high-quality, and innovative interlining solutions tailored to specific client needs.

Contact Us for More Details

Don't hesitate to contact when you need us!

English

English  中文简体

中文简体