The Ultimate Guide to Shirts Interlining: Types, Applications, and Selection

2025-09-03

Understanding the Role of Interlining in Shirt Construction

The foundation of a well-constructed shirt lies not only in the visible fabric but also in the hidden components that provide structure and shape. Interlining, a crucial yet often overlooked material, is fused or sewn between the layers of a shirt's fabric to add body, stability, and reinforcement to specific areas. Its primary function is to prevent stretching, add crispness, and maintain the intended form of the garment over time and through repeated wear and washing. From the crisp collar that frames the face to the sturdy cuffs and the neat placket, interlining is the unsung hero that ensures a shirt looks polished and professional. The choice of interlining directly impacts the drape, hand feel (the tactile quality of the fabric), durability, and overall aesthetic of the final product. Selecting the wrong type can lead to a stiff, uncomfortable shirt or, conversely, a limp and poorly structured one. Therefore, a deep understanding of shirts interlining is paramount for manufacturers, designers, and even informed consumers who value quality apparel.

The application process is equally important. The two main methods are fusing and sewing. Fusing involves using a heat-activated adhesive on one side of the interlining to bond it permanently to the shirt fabric. This method is efficient and widely used in mass production. Sewn-in interlining, often considered a mark of higher quality, is basted or stitched into place, allowing for greater breathability and a more natural drape, but it is more labor-intensive. The evolution of interlining materials, from traditional starched fabrics to modern synthetic fusibles, has significantly changed shirt manufacturing, enabling greater consistency and new design possibilities while also introducing new considerations around comfort and durability.

Key Functions of a Quality Interlining

A high-quality interlining performs several simultaneous functions without compromising the comfort of the wearer.

- Structural Reinforcement: It provides essential support to high-stress areas like the collar, cuffs, and plackets, preventing them from curling, sagging, or losing their shape.

- Shape Retention: It helps the shirt maintain its intended silhouette through countless washes and wears, combating the natural tendency of fabrics to stretch and deform.

- Enhanced Aesthetics: It contributes to a crisp, clean appearance by adding just the right amount of body and rigidity, ensuring sharp collar points and smooth surfaces.

- Drape and Hand Feel Control: The weight and flexibility of the interlining directly influence how the fabric falls (drape) and feels against the skin. A good interlining enhances without overpowering the base fabric.

- Application-Specific Performance: Specialized interlinings can offer additional properties such as washability, shrinkage control, and resistance to high temperatures during laundering.

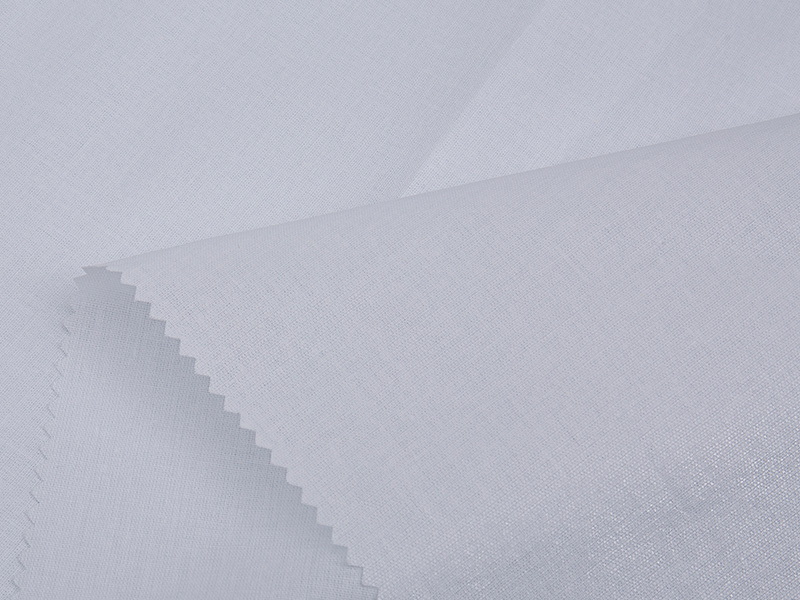

Exploring Different Types of Shirt Interlining Materials

The world of interlining materials is diverse, with each type offering a unique set of properties that cater to different shirt styles, fabrics, and price points. The choice of material is a critical decision that balances cost, desired hand feel, durability, and manufacturing process. Traditionally, interlinings were made from natural fibers like cotton or wool, but today, the market is dominated by sophisticated materials engineered for specific performance characteristics. Understanding the inherent qualities of each material is the first step in selecting the perfect interlining for any shirt project.

Woven and Non-Woven Interlinings: A Fundamental Distinction

The most fundamental categorization of interlinings is based on their construction method: woven or non-woven.

Woven Interlinings

Woven interlinings are created by weaving yarns together on a loom, much like standard shirt fabrics. This construction gives them a grain line and inherent stability along that grain. They are typically made from cotton, polyester, or a blend of both. Woven interlinings are known for their:

- Superior Durability and Stability: Their woven structure makes them strong and resistant to stretching, especially on the bias (diagonal), which is crucial for collar longevity.

- Excellent Drape: They tend to be more flexible and softer than non-wovens, resulting in a more natural and comfortable feel in the finished shirt.

- Breathability: Especially when made from natural fibers, they allow air to circulate, enhancing comfort.

However, they are generally more expensive than non-woven options due to a more complex manufacturing process.

Non-Woven Interlinings

Non-woven interlinings are manufactured by bonding fibers together using mechanical, chemical, or heat processes. There is no woven structure or grain line. They are a popular choice for many mass-market shirts due to their:

- Cost-Effectiveness: They are cheaper to produce than woven interlinings, reducing the overall cost of the garment.

- Consistency: They have uniform strength in all directions because they lack a grain.

- Versatility: They can be engineered to have a wide range of weights and stiffness levels.

The downside is that they can be less durable than wovens, sometimes becoming brittle and breaking down after repeated laundering, leading to "bubbling" delamination. They are also generally less breathable.

Comparing Common Fusible Interlining Options

The following table provides a clear comparison of the most commonly used fusible interlining materials in shirtmaking, highlighting their best applications and key characteristics.

| Material Type | Key Characteristics | Best For | Considerations |

|---|---|---|---|

| 100% Cotton Woven | Soft hand feel, excellent breathability, natural drape, good wash durability. | High-quality dress shirts, luxury shirts where comfort and a natural feel are paramount. | Can shrink; requires pre-shrinking before fusing. Higher cost. |

| Polyester/Cotton Blend Woven | Combines the comfort of cotton with the stability and shrink-resistance of polyester. Durable. | A versatile choice for a wide range of mid-to-high-end shirts. | Very popular and balanced option. Offers good value. |

| 100% Polyester Non-Woven | Inexpensive, consistent, available in various weights. Good stiffness. | Budget-friendly shirts, areas needing high stiffness (e.g., cuff reinforcement). | Can be less breathable. Potential for delamination over time if low quality. |

| Woven Nylon | Extremely lightweight, thin, and strong. Very soft hand feel. | Sheer or very lightweight delicate shirts where adding minimal weight is critical. | Can be tricky to fuse correctly due to its lightweight nature. |

How to Choose the Best Interlining for Dress Shirts

Selecting the optimal interlining for a dress shirt is a nuanced process that requires careful consideration of several interrelated factors. The goal is to achieve a perfect harmony between the outer fabric, the interlining, and the intended style of the shirt. A common mistake is to simply choose the stiffest interlining available, which often results in a rigid, uncomfortable collar that feels like cardboard against the neck. The best interlining is the one you don't notice—it provides support without compromising comfort. The process involves evaluating the characteristics of the shell fabric and matching them with an interlining that complements and enhances, rather than overwhelms, them. This section will guide you through the critical decision-making criteria to ensure a flawless result, whether you are a professional or an enthusiast. The quest for best interlining for dress shirts is central to achieving a superior product.

Matching Interlining to Shirt Fabric Weight and Composition

The weight and fiber content of your main shirt fabric are the primary determinants for your interlining choice. The principle is simple: the interlining should generally be lighter in weight than the shell fabric. A heavy interlining on a lightweight fabric will cause it to feel stiff and look unnatural, while a light interlining on a heavy fabric will fail to provide adequate structure.

- Lightweight Fabrics (e.g., Voile, Poplin, Lightweight Cotton): These require a very lightweight, soft, and drapey interlining. A thin woven cotton or polyester-cotton blend is ideal. Non-wovens should be avoided unless they are specifically engineered for sheers and are very soft. The interlining must add just enough body to prevent curling without making the delicate fabric feel bulky.

- Medium-Weight Fabrics (e.g., Standard Cotton, Oxford Cloth): This category offers the most flexibility. A medium-weight woven fusible, often a poly-cotton blend, is a standard and reliable choice. It provides a classic crispness while maintaining comfort.

- Heavyweight Fabrics (e.g., Denim, Flannel, Twill): These robust fabrics can handle a slightly heavier interlining to provide the necessary support against their inherent weight. A sturdy woven interlining or a heavier non-woven can be used. The key is to ensure the bond is strong enough to handle the stress placed on areas like the collar points.

Fiber composition also matters. For a 100% cotton shirt, a cotton or poly-cotton interlining is often preferred for its similar care requirements and breathability. For synthetic blends, a polyester-based interlining might be more compatible.

Considering Shirt Style and Desired Stiffness

The style of the shirt dictates the required level of stiffness and roll (the gentle curve of a collar). A formal business shirt demands a different feel than a casual weekend shirt.

- Formal Dress Shirts: These typically call for a medium-stiffness interlining that provides a crisp, clean look that holds throughout a long day. The collar should stand neatly without being rigid. A mid-weight woven fusible is the classic choice.

- Italian or Fashion-Forward Styles: Often characterized by a softer hand feel and a more pronounced collar roll. This look requires a softer, more pliable interlining, often a lighter woven variety, to achieve that elegant, less structured drape.

- Casual Shirts (e.g., Button-Downs): The button-down collar itself helps maintain shape, so it requires a much softer interlining to allow for the rolling and buttoning. A soft, lightweight woven is essential to avoid a clumsy, stiff look.

The Advantages of Using Fusible Interlining for Shirts

The advent and refinement of fusible interlining technology revolutionized the garment industry, and shirt manufacturing is no exception. Fusible interlining, which features a heat-activated adhesive coating on one side, has become the dominant method for applying interlining in modern production due to its significant efficiency and performance advantages. While traditional sewn-in interlinings are still valued for ultra-high-end applications, the advantages of fusible interlining for shirts are compelling for most manufacturers and consumers. These benefits range from economic factors to consistent quality and enhanced durability, making them a cornerstone of contemporary shirt production.

Production Efficiency and Consistency

The most significant advantage of fusible interlining is the dramatic increase in production speed and efficiency. The fusing process can be highly automated using fusing presses, which apply precise heat and pressure for a controlled amount of time. This automation:

- Reduces Labor Costs: It eliminates the slow, skilled handwork of basting and sewing interlining into place.

- Increases Output: Multiple parts can be fused simultaneously in a single press operation, drastically speeding up the production line.

- Ensures Uniformity: Every fused part is subjected to the exact same conditions, resulting in a consistent bond and appearance across every shirt in a production run. This eliminates the variability that can occur with manual sewing.

This consistency is crucial for brand integrity, as customers expect every shirt of the same model to look and feel identical.

Enhanced Durability and Shape Retention

When properly fused using the correct temperature, pressure, and time settings, a fusible interlining creates a permanent, monolithic bond with the shirt fabric. This bond offers several durability benefits:

- Superior Resistance to Wrinkling and Creasing: The fused panel becomes more rigid, making it more resistant to developing wrinkles during wear.

- Excellent Shape Retention: The bond helps the fabric resist the stretching forces that occur during wear and washing. This is particularly important for maintaining sharp collar points and a smooth placket over the lifespan of the shirt.

- Prevention of "Collar Roll": A well-fused interlining prevents the top layer of the collar from separating and rolling over, maintaining a neat and tidy appearance.

It is this permanent reinforcement that gives a fused shirt its characteristic crispness that often lasts longer than that of a sewn-in interlining, which can shift or bunch inside its casing over time.

Caring for Your Shirts: Interlining Washability and Longevity

The relationship between interlining and garment care is inextricable. How you launder your shirts has a direct and profound impact on the performance and lifespan of the interlining. Improper care is the leading cause of interlining failure, which manifests most commonly as delamination—the separation of the interlining from the shell fabric, often called "bubbling." This unsightly issue renders a shirt unwearable in professional settings. Understanding the washability of shirt interlining is therefore not just a manufacturing concern but also a critical knowledge point for consumers who wish to protect their investment in quality clothing. Proper care ensures that the structural integrity and aesthetic appeal of the shirt remain intact for years to come.

Best Laundering Practices to Prevent Delamination

Delamination occurs when the adhesive bond of a fusible interlining is broken down. This can be caused by excessive heat, harsh chemicals, or mechanical abrasion during washing and drying. Adhering to the following best practices can significantly reduce the risk:

- Follow Care Labels Diligently: The manufacturer's instructions are the first and most important source of information. They are based on the specific materials and interlining used.

- Turn Shirts Inside Out: This simple step protects the outer surface and the fused areas (cuffs, collar) from direct abrasion against the drum of the washing machine or other garments.

- Use Gentle Cycles and Cold/Cool Water: Aggressive wash cycles cause excessive friction and stress on the adhesive bonds. Cold water washing is gentler on fabrics and adhesives and also conserves energy.

- Choose Mild Detergents: Harsh detergents, especially those containing strong bleach or enzymes, can degrade the adhesive over time. Opt for mild, liquid detergents.

- Avoid Excessive Heat in Drying: High heat in tumble dryers is a primary culprit for delamination. It can reactivate the adhesive unevenly, leading to bubbling. The safest method is to air dry shirts. If machine drying is necessary, use the lowest heat setting or an air-fluff (no heat) cycle and remove the shirts while they are still slightly damp to ease ironing.

Ironing and Steaming Fused Shirt Components

Ironing is often necessary to restore a shirt's crisp appearance, but it must be done correctly to avoid damaging the interlining.

- Use the Correct Iron Temperature: Always use a temperature setting appropriate for the shirt's primary fabric (usually cotton). Avoid using the linen or maximum heat setting unnecessarily.

- Employ a Press Cloth: Placing a thin cloth (like a muslin or handkerchief) between the iron and the shirt collar or cuff provides a buffer against direct heat and prevents scorching or shining the fabric.

- Avoid Ironing Over the Fused Seam Allowances: The edges where the interlining stops can leave a slight ridge. Ironing directly over this ridge can create a sharp crease that stresses the bond. Iron up to the edge, not over it.

- Steaming as an Alternative: A garment steamer is a gentler option for removing wrinkles. It uses heat and moisture without applying direct pressure, posing virtually no risk to the fused interlining bond. It is excellent for refreshing a shirt between washes.

By adopting these careful practices, the longevity of fusible interlining in shirts can be maximized, ensuring that the collar and cuffs remain smooth, structured, and bubble-free for the life of the garment.

Where to Source Quality Shirt Interlining Materials

For designers, manufacturers, and serious hobbyists, finding a reliable source for quality interlining is as important as the design of the shirt itself. The supplier you choose will determine the consistency, performance, and availability of the materials that form the foundation of your products. The market offers a wide spectrum of sources, from large international wholesalers to specialized niche vendors. The key is to find a partner that provides not just a product, but also technical support, consistency, and reliability. Knowing where to source quality shirt interlining is a critical step in the production chain, influencing everything from prototyping to mass production.

Key Considerations When Choosing a Supplier

Selecting an interlining supplier should not be based on price alone. Several factors contribute to a successful supplier relationship.

- Product Range and Specialization: A good supplier will offer a wide range of weights, materials (woven, non-woven, knit), and resin types (e.g., low-temperature fuse, washable) to meet different needs. Some suppliers specialize in products for specific markets, like high-fashion or workwear.

- Quality Consistency and Testing: Inquire about their quality control processes. Do they test for shrinkage, wash durability, and bond strength? Consistent quality from roll to roll is non-negotiable for professional results.

- Technical Data and Support: Reputable suppliers provide technical data sheets for their products, detailing fusing parameters (temperature, pressure, time), shrinkage rates, and care instructions. Access to knowledgeable representatives who can advise on material selection is invaluable.

- Minimum Order Quantities (MOQs): Large manufacturers can order in bulk, but smaller designers or hobbyists need suppliers with low MOQs, allowing them to purchase smaller amounts for sampling and small production runs.

- Lead Times and Reliability: Consistent and dependable delivery schedules are essential for maintaining a smooth production flow. Evaluate their track record for on-time delivery.

Types of sourcing channels

The best channel for you depends on your volume, expertise, and needs.

- Specialized Textile Wholesalers: These companies carry interlining alongside other sewing supplies like threads, elastics, and fabrics. They are a good option for those who want to source everything from one place and often cater well to small businesses.

- Direct from Interlining Mills: Large-scale manufacturers often buy directly from the mills that produce the interlining. This offers the best pricing for huge volumes but requires significant technical expertise in-house and very large MOQs.

- Online Marketplaces and Retailers: For hobbyists and very small-scale makers, online fabric and craft stores can be a source for retail-packed interlining. The selection may be limited, and the cost per meter is higher, but it provides accessibility for those just starting.

Contact Us for More Details

Don't hesitate to contact when you need us!

English

English  中文简体

中文简体