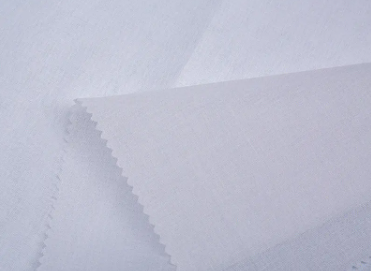

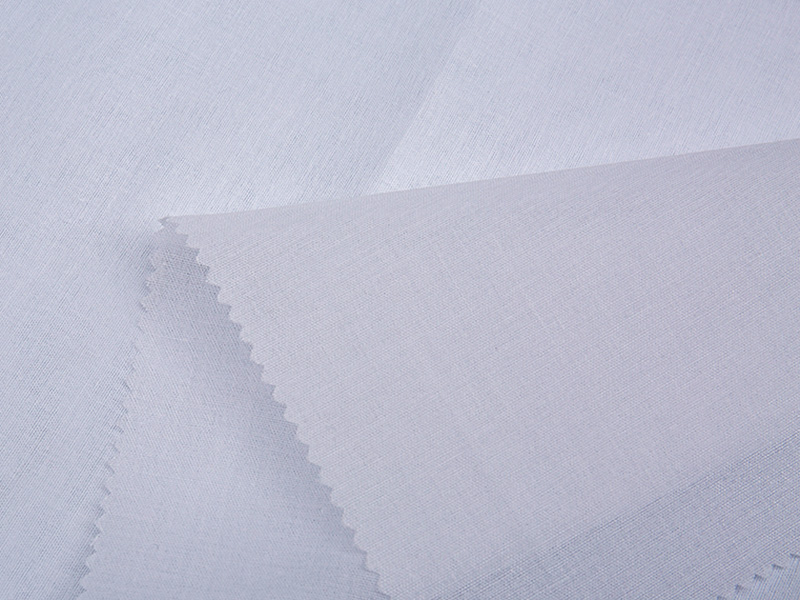

How High Elasticity Interlining Improves Fabric Performance and Durability

2026-01-14

In modern apparel engineering, internal support materials significantly impact garment quality. A well-designed interlining layer influences performance, comfort, and long-term durability. High Elasticity Interlining is engineered to provide flexible support beneath outer fabrics while allowing multidirectional extension without permanent deformation. This makes it essential for garments requiring dynamic movement, precise shaping, and structural integrity.

Founded in 2002 and based in Jiangsu Province, China, Hetai Textile has developed over two decades into a full-spectrum enterprise specializing in the development, production, sales, and service of interlining fabrics. Our facilities include weaving, dyeing, and coating workshops with advanced production lines and a top-tier technical team. We continuously innovate to maintain product quality at the industry's forefront while adhering to comprehensive quality control systems.

Performance Metrics of High Elasticity Interlining

Performance of elastic interlining fabric tensile performance is evaluated through tensile strength, elongation, recovery rate, and bonding stability. Optimizing these metrics ensures garments maintain structure while providing wearer comfort.

| Performance Metric | High Elasticity Interlining | Conventional Interlining |

| Tensile Elongation (%) | 15–25% | 3–7% |

| Elastic Recovery Rate | ≥85% | ≤60% |

| Wash & Wear Durability | ≥50 Industrial Wash Cycles | 20–30 Industrial Wash Cycles |

| Bond Strength (fusible) | ≥12 N/5 cm | 6–8 N/5 cm |

Comparison with Conventional Interlining

Unlike traditional fusible or nonwoven interlining materials that primarily provide rigidity, high elasticity interlining for structured garments offers a balanced combination of flexibility and structural control. This makes it particularly suitable for activewear, tailored garments, and multi-layer constructions where motion resilience is critical.

- Conventional interlining: Increases stiffness but limits stretch tolerance.

- High elasticity interlining: Enhances comfort during dynamic activity while preserving garment silhouette.

Engineering Design Considerations

Integrating durable stretch interlining for activewear requires careful engineering to align the interlining with shell fabrics and adhesives. Key considerations include:

- Matching elongation properties of the interlining with outer fabric to prevent delamination or puckering.

- Using appropriate adhesives for low temperature fusible elastic interlining to protect sensitive fabrics.

- Monitoring elastic interlining bonding strength metrics for consistent durability across production runs.

Industry Standards and Market Insights 2024–2025

According to the latest report by Industry Research, the global interlining market is experiencing robust growth due to increasing demand for performance textiles and structured garments. Innovations focus on enhancing stretch compatibility, adhesive technologies, and traceable quality control systems. ([industryresearch.biz](https://www.industryresearch.biz/market-reports/interlinings-fabric-market-112820?utm_source=chatgpt.com))

Source: Industry Research – Interlinings Fabric Market Insights 2025

China continues to lead production growth in high-performance interlining solutions, particularly those optimized for tensile performance and activewear applications. Market insights from Future Market Insights indicate that adoption of elastic interlining fabric tensile performance solutions is expected to rise steadily in the next five years. ([futuremarketinsights.com](https://www.futuremarketinsights.com/reports/garment-interlining-market?utm_source=chatgpt.com))

Source: Future Market Insights – Garment Interlining Market Growth

Incorporating High Elasticity Interlining into garment construction enhances dynamic comfort, recovery, and long-term durability. By comparing conventional and elastic interlining solutions, engineers and manufacturers can optimize textile systems for specific use cases, from structured suits to activewear designed for multidirectional motion. Hetai Textile’s advanced production capabilities and strict quality management ensure that high elasticity interlining fabrics meet stringent performance standards for modern apparel engineering.

Frequently Asked Questions

- What is High Elasticity Interlining and why is it important?

It is a flexible interlining fabric designed to provide support while allowing multidirectional stretch, improving garment structure, comfort, and durability.

- How does durable stretch interlining for activewear enhance garment performance?

By offering high tensile strength and recovery, it maintains shape during dynamic movement and repeated washing.

- What should manufacturers consider when selecting elastic interlining bonding strength metrics?

They should ensure bond strength is compatible with shell fabrics and adhesive types to prevent delamination.

- Can high elasticity interlining for structured garments replace all conventional interlining types?

It can replace conventional interlining in garments requiring stretch and recovery but may not be suitable for applications needing extreme stiffness.

- What are the key trends for elastic interlining fabrics in 2025?

Market trends emphasize improved stretch compatibility, low-temperature fusible adhesives, and traceable quality control systems to enhance performance textiles.

Contact Us for More Details

Don't hesitate to contact when you need us!

English

English  中文简体

中文简体