The Complete Guide to Pocketing Fabric: Types, Applications, and Selection

2026-01-08

In the world of garment construction, the unseen components often determine the longevity, drape, and overall quality of the finished piece. Among these, pocketing fabric plays a pivotal role. Far more than just a simple lining for pockets, it is a specialized material engineered for durability, flexibility, and comfort. This guide delves into the intricacies of pocketing fabric, exploring its various types, ideal applications, and key selection criteria to empower designers, manufacturers, and procurement specialists with the knowledge needed to make informed decisions.

What is Pocketing Fabric? A Foundational Overview

Pocketing fabric is a lightweight, yet robust textile specifically designed for constructing pocket bags in clothing. Its primary function is to form a durable, smooth, and comfortable interior layer that can withstand repeated insertion and removal of hands and objects. Unlike standard lining fabrics, pocketing materials are engineered for high abrasion resistance, tear strength, and often feature a low-friction surface to facilitate easy hand access.

Key characteristics of premium pocketing fabric include:

- Durability: Must endure constant wear and friction without pilling or tearing.

- Breathability: Should allow air circulation for wearer comfort, especially in garments like suits and trousers.

- Soft Hand Feel: Needs to be comfortable against the skin.

- Dimensional Stability: Should resist shrinking or stretching to maintain the garment's shape.

- Colorfastness: Colors should not bleed onto the main garment fabric during washing or with perspiration.

Companies with integrated production capabilities, like Nantong Hetai Textile Technology Co., Ltd., understand that achieving this balance requires control over the entire process—from weaving the base cloth to specialized dyeing and finishing—ensuring the final product meets stringent performance standards.

Five Specialized Types of Pocketing Fabric and Their Uses

Selecting the right pocketing fabric depends heavily on the garment type, desired aesthetics, and functional requirements. Here is a detailed comparison of the most common varieties.

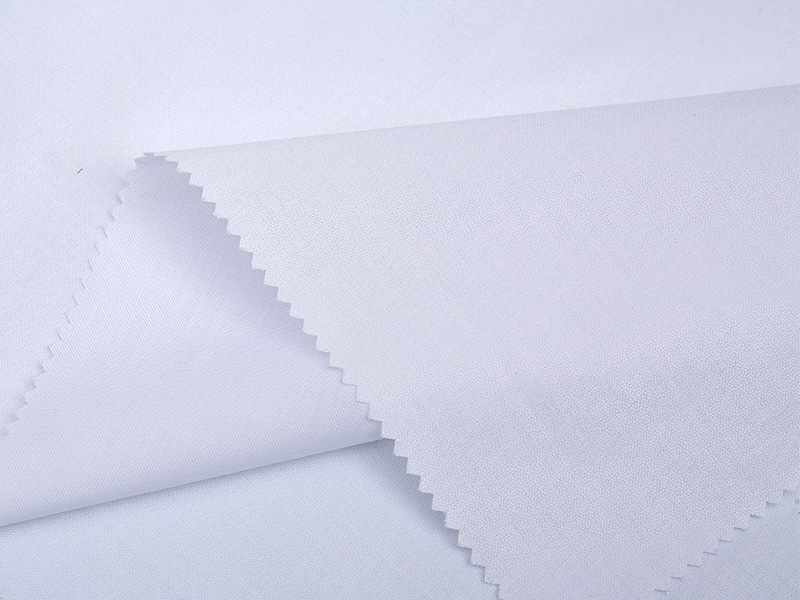

1. Twill Pocketing: The Durable Standard

Renowned for its diagonal weave pattern, twill pocketing is a workhorse in the industry. Its structure grants it superior strength and durability compared to plain weaves.

- Primary Use: Ideal for heavy-duty applications like denim jeans, workwear, and trousers.

- Key Features: Excellent abrasion resistance, drapes well, and has a distinctive texture.

- Consideration: Can be slightly heavier than other types.

Understanding the nuances of how to choose durable pocketing fabric for trousers often leads professionals to high-quality twill constructions, as they provide the necessary resilience for daily use.

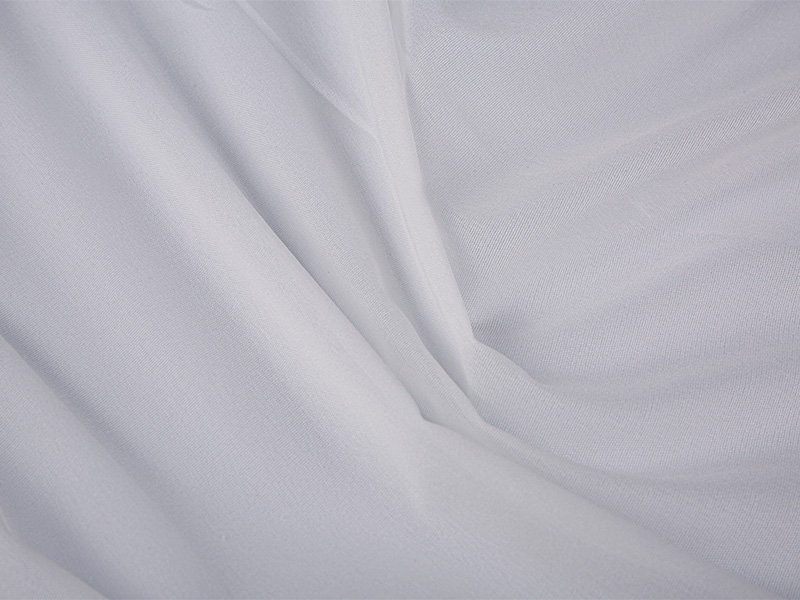

2. Sateen Pocketing: The Smooth and Silky Option

Sateen pocketing features a weave where warp threads float over multiple weft threads, creating a remarkably smooth, lustrous surface with a soft hand feel.

- Primary Use: Premium suits, blazers, dress pants, and high-end tailored clothing where a luxurious feel is paramount.

- Key Features: Low friction allows for easy hand access, exceptionally soft, and adds a touch of interior luxury.

- Consideration: May be less abrasion-resistant than twill due to the float threads.

3. Printed or Patterned Pocketing: For Branding and Aesthetics

This category involves applying designs, logos, or patterns onto standard pocketing fabrics like twill or sateen.

- Primary Use: Fashion-forward denim, branded apparel, children's clothing, and garments where the interior is part of the design statement.

- Key Features: Enhances brand identity and customer experience; turns a functional component into a design element.

- Consideration: Print quality must be durable to resist fading from washing and friction.

The process of printing custom designs on pocket lining material requires precise technology and color management to ensure the patterns remain vibrant and intact throughout the garment's life.

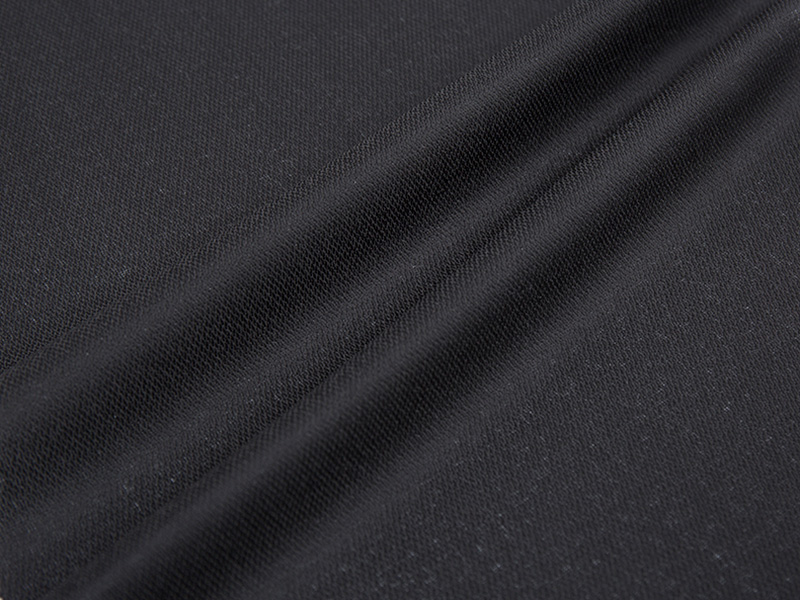

4. Stretch Pocketing: For Flexible and Form-Fitting Garments

Incorporating a small percentage of elastane (spandex) into the weave or knit, stretch pocketing provides essential flexibility.

- Primary Use: Activewear, stretch denim, fitted pants, and any garment requiring freedom of movement.

- Key Features: Moves with the body, recovers its shape, and reduces stress on pocket seams.

- Consideration: Must maintain recovery and not become baggy over time.

5. Organic or Sustainable Pocketing: Meeting Eco-Conscious Demands

Made from certified organic cotton, recycled polyester, or other sustainable fibers, this type caters to the growing market for environmentally responsible textiles.

- Primary Use: Sustainable fashion brands, eco-conscious apparel lines, and products with green certifications.

- Key Features: Reduced environmental footprint, often GOTS or OEKO-TEX certified, appealing to a specific consumer base.

- Consideration: Performance must match conventional options; can sometimes come at a premium cost.

For brands looking to enhance their sustainability profile, identifying sustainable and breathable pocket bag fabric suppliers is a critical step in the supply chain. A supplier's commitment to innovation, like Hetai's ongoing R&D in eco-friendly finishes, can be a significant advantage.

Comparison Table: Pocketing Fabric Types at a Glance

| Fabric Type | Best For | Key Advantage | Potential Drawback |

|---|---|---|---|

| Twill | Jeans, Workwear, Trousers | Superior Durability & Abrasion Resistance | Can Be Heavier |

| Sateen | Suits, Blazers, Dress Pants | Ultra-Smooth Feel & Luxurious Drape | Less Abrasion-Resistant |

| Printed/Patterned | Fashion Denim, Branded Apparel | Enhanced Aesthetics & Branding | Print Durability is Crucial |

| Stretch | Activewear, Stretch Denim | Flexibility & Comfort with Movement | Requires Good Elastic Recovery |

| Organic/Sustainable | Eco-Conscious Fashion Lines | Reduced Environmental Impact | Possible Higher Cost |

How to Select the Right Pocketing Fabric: A Practical Guide

Making the correct choice involves balancing several technical and practical factors.

Assessing Fabric Weight and Thickness

The weight (often in GSM - grams per square meter) directly impacts durability and drape.

- Lightweight (80-120 GSM): Suitable for lightweight trousers, shirts, and blouses. Offers comfort but may not be ideal for heavy items.

- Medium Weight (120-150 GSM): The most versatile range, excellent for standard trousers, chinos, and mid-weight jackets.

- Heavyweight (150+ GSM): Reserved for denim, workwear, and outerwear where maximum durability is required.

A common query in sourcing is about the best weight for pocketing fabric in denim jackets, which typically falls into the medium to heavyweight category to match the ruggedness of the denim itself.

Evaluating Performance: Breathability vs. Water Resistance

This is a key functional trade-off. The choice depends entirely on the garment's end use.

- Breathable Fabrics: Natural fibers like cotton or specific weaves promote air circulation. Essential for formal wear and everyday clothing to prevent clamminess.

- Water-Resistant Fabrics: Treated with a durable water repellent (DWR) finish or made from synthetic fibers. Crucial for outdoor and performance apparel to keep contents dry.

It is challenging to find a single fabric that excels in both. For instance, breathable vs water-resistant pocketing materials serve two distinct markets. A technical supplier with advanced coating capabilities can offer solutions tailored to each need, whether it's a moisture-wicking finish for sportswear or a light DWR coating for outdoor gear.

The Importance of Color Matching and Fastness

Color is not merely aesthetic; it's functional.

- Color Matching: Pocketing should complement or discreetly match the garment's main fabric. Dark garments require dark pocketing to prevent show-through.

- Color Fastness: The fabric must resist bleeding dye during washing (wash fastness) and when wet with perspiration (perspiration fastness). Poor fastness can ruin a garment.

Innovation and Quality: The Role of an Integrated Manufacturer

The consistency and performance of pocketing fabric are deeply tied to the manufacturer's expertise and process control. An integrated operation, such as that of Nantong Hetai Textile Technology Co., Ltd., which encompasses weaving, dyeing, and coating under one roof, offers distinct advantages:

- Vertical Quality Control: Monitoring quality at every stage, from yarn to finished fabric, ensures fewer defects and higher consistency.

- R&D Capability: In-house research and development teams can innovate on demand, creating custom solutions for specialized pocketing for technical workwear or developing new sustainable finishes.

- Supply Chain Efficiency: Streamlined production reduces lead times and allows for greater flexibility in meeting specific client requirements, whether for small custom orders or large bulk production.

- Technical Support: Direct access to technical experts helps clients solve application challenges and select the optimal fabric for their project.

Founded in 2002 and with a dedicated facility established in 2017 in Hai'an, Nantong, Hetai's two-decade journey reflects a deep commitment to mastering the entire interlining and pocketing fabric production process, ensuring every meter of fabric meets the forefront of industry quality.

Frequently Asked Questions (FAQ)

1. What is the most durable type of pocketing fabric?

Heavyweight cotton twill is generally considered the most durable for everyday wear. Its tight, diagonal weave structure provides exceptional resistance to abrasion and tearing, making it the go-to choice for denim and workwear.

2. Can pocketing fabric be recycled or sustainable?

Yes. The market now offers pocketing made from recycled materials (like post-consumer plastic bottles) or certified organic cotton. When sourcing, look for relevant certifications such as GRS (Global Recycled Standard) or GOTS (Global Organic Textile Standard) to ensure authenticity.

3. How do I prevent pocketing fabric from fading or bleeding color?

Select fabrics from suppliers that prioritize high colorfastness standards during dyeing and finishing. Conduct pre-production tests for wash and perspiration fastness. Proper garment care labels recommending cold wash and mild detergents also help.

4. Is stretch pocketing necessary for all fitted garments?

While not always necessary, it is highly beneficial. Stretch pocketing (with 2-5% elastane) allows the pocket bag to move with the garment and the body, reducing strain on seams and preventing the pocket from pulling or deforming the outer fabric of tight-fitting pants or activewear.

5. What should I look for in a reliable pocketing fabric supplier?

Prioritize suppliers with:

- Integrated manufacturing capabilities for quality control.

- A proven track record and industry experience.

- Strong R&D to offer innovative and custom solutions.

- Comprehensive quality certifications (e.g., OEKO-TEX Standard 100).

- Responsiveness and ability to provide technical support and samples.

Contact Us for More Details

Don't hesitate to contact when you need us!

English

English  中文简体

中文简体