Mastering the Art of Structure: A Deep Dive into Light-weight Interlining

2025-12-05

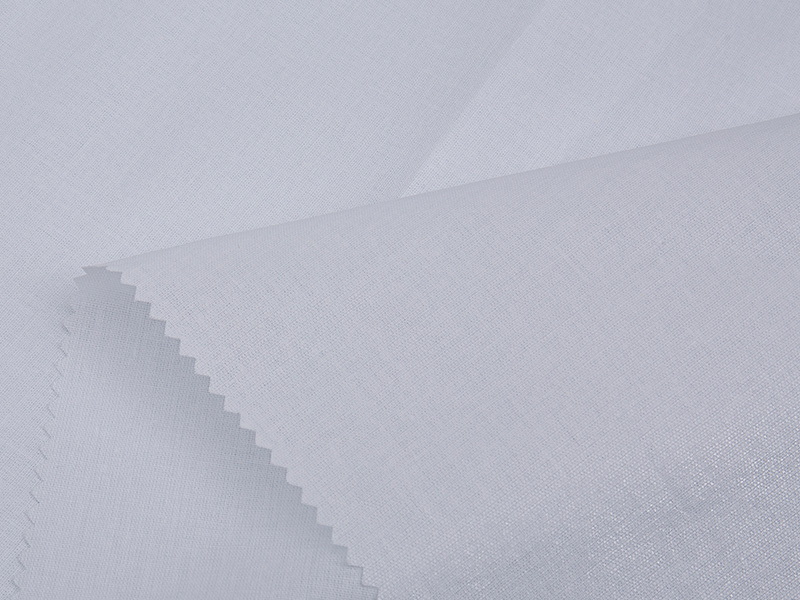

In the world of professional garment construction and high-quality tailoring, the hidden support of light-weight interlining is often the difference between a mediocre finish and a truly exceptional piece. This essential material provides subtle yet necessary structure, drape, and stability to fabrics without adding bulk or stiffness. For seasoned designers and dedicated sewing enthusiasts alike, understanding the nuances of this critical component is paramount for achieving professional results. This comprehensive guide will explore the definitions, types, applications, and selection criteria for this fundamental textile component, ensuring your projects achieve optimal form and longevity. We will delve into specific usage cases, from delicate silks to structured jacket fronts, all while maintaining the fabric's intended aesthetic and feel.

What is Light-weight Interlining and Why Does It Matter?

Defining Light-weight Interfacing

Light-weight interlining, often synonymously called interfacing, is a supportive fabric placed between the garment fabric and the facing or lining. Its primary function is to lend stability, prevent stretching, and reinforce specific areas like collars, cuffs, waistbands, and button plackets. Unlike heavier alternatives used for structured outerwear, the light-weight variant is specifically engineered to be virtually undetectable, preserving the soft hand and natural drape of lighter fabrics such as chiffon, silk, and lightweight cotton. Its weight is typically measured in grams per square meter (GSM) and is carefully matched to the outer fabric to avoid an overly stiff or 'boardy' appearance. The careful selection process requires an understanding of both the desired final structure and the textile's fiber composition.

- Structural Integrity: Provides the necessary firmness to areas that require crispness, such as shirt collars and cuffs.

- Shape Retention: Helps garments maintain their intended shape over time and through wear, especially in bias-cut areas.

- Pucker Prevention: Stabilizes fabric around closures (buttonholes, zippers) to prevent pulling or distorting.

- Hand Preservation: Adds support while ensuring the overall feel and softness of the main fabric remain unchanged.

The Crucial Role in Garment Construction

The strategic use of light-weight interlining is a hallmark of high-end, professional construction. Its placement dictates the final flow and structure of the garment. In contrast to simply lining a garment, interlining is directly fused or sewn to the fashion fabric, providing targeted support where it is most needed. This practice is particularly vital in ready-to-wear and couture where maintaining the fabric’s original fluidity while preventing fraying or undue stress on seams is essential. A common misconception is that the interlining's weight should match the outer fabric; in reality, it often needs to be slightly lighter to avoid compromising the drape. For example, a crisp cotton voile may require a woven light-weight interfacing to maintain its breathability and subtle sheen.

- Collar and Cuffs: Ensures a sharp, smooth turn of the cloth that withstands repeated washing and pressing.

- Hemlines: Provides a stable base for an invisible hem, especially on curved or bias edges.

- Pockets: Reinforces the opening of patch or welt pockets against frequent use and stress.

- Waistbands: Gives necessary body for a clean fit and prevents the band from rolling or collapsing.

Exploring Key Types and Their Specific Applications

Non-woven light-weight interlining uses and Benefits

Non-woven light-weight interlining uses span a vast range of applications due to their versatility and economical nature. Non-woven interlinings are manufactured by bonding fibers together through heat, chemical, or mechanical processes, rather than weaving or knitting them. This structure means they have no grainline, making them easy to cut and apply in any direction, minimizing fabric waste. They are particularly effective when a smooth, uniform support is needed without concern for the fabric's movement or natural elasticity, such as in structured home décor items or simple garment accessories. However, it is crucial to test the stiffness and drape, as some lower-quality non-wovens can feel papery. For projects requiring a minimal, discreet lift, the lightest-weight non-wovens are the preferred choice, offering excellent stability without noticeable stiffness, often featuring a subtle dot adhesive for fusion.

- Economy and Efficiency: Often the most cost-effective option and easy to apply due to the lack of grain.

- Uniform Stability: Provides consistent, all-directional support, which is ideal for stabilizing edges.

- Versatile Bonding: Available in many weights and colors (white, black, charcoal) to match the main fabric.

Comparison of Non-Woven Attributes:

| Attribute | Non-Woven (Light-Weight) | Woven (Heavier Weight) |

| Grain Direction | None (All-directional stability) | Requires matching grain to the main fabric |

| Drape Impact | Can potentially restrict drape if too stiff | Maintains natural fabric drape and elasticity |

| Best For | Collars, cuffs, facing edges, appliqué | Full fronts of tailored jackets, areas needing stretch support |

Woven light-weight interlining vs knit Interlinings

The debate between woven light-weight interlining vs knit boils down to the desired movement and stability of the final garment. Woven interlinings are constructed on a loom, sharing the same warp and weft structure as traditional woven fabrics. This means they possess a distinct grainline, and when cut correctly (matching the grain of the fashion fabric), they offer superb shape retention while maintaining the fabric's natural drape and breathability. Knit interlinings, on the other hand, are constructed with interlocking loops, giving them inherent stretch, making them the superior choice for knits, jerseys, or woven fabrics with an elastane content where movement is essential. A key factor in selecting between these two is the direction of the stretch: a two-way stretch knit interlining can prevent 'bagging' in high-stress areas like the elbows or knees, while a stable woven choice prevents stretching in areas like the neckline. Both types are often available as fusible options, offering a cleaner application than sew-in varieties.

- Woven Advantage: Offers high directional stability and is essential for achieving the sharpest, tailored finishes on woven fabrics.

- Knit Superiority: Provides flexible support, moving with the main fabric, which is critical for comfortable stretch apparel.

- Shear Factor: Knit interlinings have a softer 'hand' than many wovens and are less likely to show through.

Comparison of Woven and Knit Types:

| Characteristic | Woven Light-weight Interlining | Knit Light-weight Interlining |

| Structure | Warp and Weft Threads (Has Grainline) | Interlocking Loops (Stretch in one or two directions) |

| Flexibility | Low (High stability) | High (Ideal for stretch and comfort) |

| Suitable Fabrics | Chiffon, linen, cotton voile (Woven) | Jersey, Lycra blends, stretch velvet (Knit) |

Selecting the Right Interlining for Specialized Fabrics

Ensuring Success with Fusible light-weight interlining for delicate fabrics

Using fusible light-weight interlining for delicate fabrics requires precision and caution, as improper application can easily damage the main material. Delicate fabrics, such as silk charmeuse, fine georgette, and lace, are sensitive to heat, pressure, and steam, all of which are necessary for the fusing process. The key is to select a fusible interlining with a very low-temperature melting adhesive and apply it using a press cloth and minimal steam, relying more on pressure than heat. Furthermore, the interlining itself must be extremely light and soft to maintain the luxurious drape of the delicate fabric. Using a sew-in interlining is often a safer alternative for the most heat-sensitive materials. When fusing, the adhesive side must not be allowed to touch the iron or the press cloth directly, and the pressing time should be significantly shorter than the standard recommendation. Professionals often opt for all-over dot-coated adhesives rather than the heavier scatter-coated versions to minimize the change in the fabric's hand.

- Low-Temp Adhesive: Look for interlinings specifically labeled for 'delicate' or 'silk' application to prevent scorching.

- Pressure Over Heat: Maximize even pressure and minimize heat settings during application to protect the fabric's fibers.

- Color Matching: Always choose a color that perfectly matches the delicate fabric (e.g., sheer white or black) to prevent show-through.

Comparison of Application Methods for Delicate Fabrics:

| Method | Fusible (Low-Temp) | Sew-In (Non-Fusible) |

| Heat Risk | High (Requires meticulous testing) | None |

| Application Time | Faster | Slower (Requires precise stitching) |

| Effect on Hand | Slightly firmer due to adhesive | Maintains original hand and drape perfectly |

Tailoring Support: Best sheer fabric interlining solutions

Finding the best sheer fabric interlining solutions poses a unique challenge: providing structure without being visible. Sheer fabrics, like organza, chiffon, and voile, demand an interlining that is either entirely transparent or perfectly matched in color and fineness. The most common solution involves using a sheer woven interlining, such as organza itself (often silk organza), as a sew-in option. This method provides light, crisp support while remaining virtually invisible due to its open weave. For fusible options, the industry standard is often a very fine tricot knit or a gossamer, point-bonded non-woven. These materials are engineered to have a low-sheen finish and minimal adhesive visibility. When working with extremely light colors, selecting a crisp white or even a skin-toned interlining can prevent the 'shadow' effect that black or charcoal options would create. The placement of the interlining should be limited strictly to the areas requiring structure to avoid an all-over stiff appearance that undermines the fabric's intended transparency and flow.

- Silk Organza: The traditional, high-end sew-in solution that is stable yet sheer.

- Tricot Knit: An excellent, very fine fusible option that offers a degree of invisible stretch support.

- Minimize Overlap: Ensure all edges are cleanly trimmed to prevent an unsightly line of demarcation under the sheer fabric.

Practical Guide: How to choose light-weight interfacing for apparel

Essential Testing Procedures

Knowing how to choose light-weight interfacing for apparel is less about textbook rules and more about practical, real-world testing. The golden rule is: always test the interlining with the actual fashion fabric before cutting the main garment pieces. This involves testing both the feel (or 'hand') and the fusing performance. To test the hand, fuse a small swatch of the interlining onto the main fabric and compare the result to the untouched main fabric. The fused section should feel only slightly firmer, not significantly stiffer or heavier. For the fusing test, check for adhesion failure (peeling) and, crucially, for 'strike-through'—when the adhesive melts completely and penetrates the fashion fabric, leaving a shiny residue on the right side. This step is non-negotiable, particularly when working with fusible light-weight interlining for delicate fabrics, as a failed test can ruin expensive material. A successful test will show complete, bubble-free bonding and a professional-grade finish.

- The 'Hand' Check: The interlining should be a full shade lighter in weight and feel than the main fabric.

- Drape Test: Compare the drape of the interfaced swatch with the original fabric to ensure the desired fluidity is maintained.

- Shrinkage Test: Pre-treat (pre-wash or steam) both the interlining and the main fabric before use to prevent later puckering.

Interlining Selection Checklist:

| Check Factor | Standard Requirement | Reason |

| Weight Match | Interlining < Fabric (Lighter) | To avoid adding stiffness and bulk. |

| Color Match | Interlining = Fabric (Same or lighter) | To prevent show-through, especially on sheer fabrics. |

| Grain Match (Woven) | Interlining Grain = Fabric Grain | To provide stable, directional support. |

Tips for Seamless Application

Seamless application of light-weight interlining is a skill refined through experience, yet a few professional tips can dramatically improve outcomes. When using a fusible type, ensure the ironing surface is perfectly flat and use a Teflon sheet or press cloth to protect the garment fabric and the iron plate. Proper pressure and timing are essential; instead of gliding the iron, lift and press firmly to bond the adhesive dots thoroughly. For sew-in applications, especially when dealing with sheer or fine fabrics, trimming the interlining edges slightly narrower than the garment piece (a technique known as 'under-trimming') can eliminate bulk at the seam line, resulting in a cleaner, flatter finish. When working with non-woven light-weight interlining uses, remember there is no need to worry about the grainline, simplifying the layout process. Finally, allow the newly interfaced piece to cool completely on a flat surface before moving it; this cooling period is critical for the adhesive to fully cure and achieve maximum bond strength, preventing premature peeling or bubbling.

- Cooling Time: The most overlooked step—allow 10-15 minutes for the adhesive to set fully after pressing.

- Edge Trimming: Trim the interlining away from the seam allowance to avoid bulk in the stitching line.

- Use a Clapper: For tailored areas like collars, use a wooden clapper after fusing to flatten the layers and 'set' the crispness.

FAQ

Can I use fusible interlining on delicate fabrics like chiffon?

Yes, but extreme care must be taken. For fusible light-weight interlining for delicate fabrics, you must select an interlining with a very low-temperature adhesive, specifically designed for heat-sensitive materials. You should always use a pressing cloth and rely on firm pressure for 10-15 seconds per area, rather than high heat. For the most delicate or sheerest chiffons, a sew-in light-weight interlining, such as silk organza or a fine woven cotton, is often the preferred and safer professional solution, as it eliminates the risk of heat damage and maintains the fabric's original hand and drape perfectly. Always pre-test a small, inconspicuous swatch.

What is the key difference between woven and non-woven light-weight interlining in terms of stability?

The key difference lies in their structure and directional stability. Non-woven light-weight interlining uses chemically or heat-bonded fibers, offering all-directional stability; it's equally stable in all directions because it has no grain. This is excellent for simple, uniform reinforcement. In contrast, woven light-weight interlining vs knit options are constructed with a clear grainline (warp and weft). When applied with the grain matching the fashion fabric, the woven type offers superior directional stability, preventing stretch along the bias or warp/weft lines while maintaining the fabric's natural movement and breathability along the grain. Knit interlinings offer the opposite: deliberate, built-in stretch.

How do I prevent my light-weight interfacing from bubbling after washing?

Preventing bubbling begins with proper preparation. The most common cause of bubbling is differential shrinkage between the main fabric and the interlining. To combat this, you must pre-treat or pre-shrink both materials identically before fusing—pre-wash the fabric and steam or soak the interlining. Secondly, ensuring a complete and professional bond during the initial application is vital. When learning how to choose light-weight interfacing for apparel, ensure the heat setting is appropriate for the adhesive (not just the fabric) and, most importantly, allow the interfaced piece to cool and cure on a flat surface for at least 15 minutes before handling or stitching. This cooling process finalizes the bond, locking the layers together permanently.

Contact Us for More Details

Don't hesitate to contact when you need us!

English

English  中文简体

中文简体