Ultimate Guide to Selecting and Using Adhesive Interlining Fabric for Professional Garment Construction

2025-12-11

Understanding What Adhesive Interlining Fabric Is

Definition and Core Functions

Adhesive interlining fabric refers to a special type of interfacing material that has a fusible adhesive layer on one side, allowing it to bond with the main fabric when heat and pressure are applied. Its core function is to provide structure, stability, support, and shape retention to various garments — from shirts and dresses to tailored jackets and light cotton garments. Unlike sew‑in interlining, which requires stitching, adhesive interlining simplifies production by fusing directly to the fabric, saving time and enabling cleaner seams. This makes it especially useful for lightweight garments, garments needing crisp collars or cuffs, and designs where minimal bulk is desired.

- Provides body and structure to fabrics that are otherwise too soft or flimsy.

- Prevents stretching or distortion over time, especially in high‑stress areas like collars, cuffs, waistbands, or hemlines.

- Enables clean, crisp edges and seams without visible stitching lines from interfacing.

- Simplifies garment construction by eliminating the need for hand or machine sewing of interfacing.

Why Use Adhesive Interlining Fabric — Key Benefits

The use of adhesive interlining offers several advantages over traditional methods. First, it significantly speeds up the garment manufacturing process, since the interlining is fused rather than sewn in. This is particularly beneficial for production environments or DIY garment makers seeking efficiency. Second, it delivers consistency — each piece receives the same amount of structure and support, which is crucial for tailored garments or pieces where symmetry matters. Third, by adding stability, it extends the lifespan of the garment: hems hold their shape, collars don’t droop, and fabrics don’t sag or stretch out. Finally, it supports design flexibility: because adhesive interlining can be cut to shape and fused precisely, designers can craft intricate or lightweight garments that still maintain structure.

- Faster production: no need for manual stitching of interfacing.

- Uniform quality and consistency across multiple pieces.

- Enhanced durability and shape retention of garments over time.

- Flexibility for complex designs with minimal bulk or weight.

Long‑Tail Use Cases — Matching Fabric to Purpose

Using Lightweight Adhesive Interlining Fabric for Cotton Garments

When working with cotton garments — especially light or medium‑weight cotton — selecting a lightweight adhesive interlining fabric for cotton garments can make a major difference. Cotton tends to drape softly, and heavy interfacing could weigh it down or make it feel stiff. By contrast, a lightweight, fusible interlining adds subtle structure to cuffs, collars, front plackets and seams, giving garments a more polished, refined finish without compromising comfort or breathability. For shirts, blouses, or summer dresses, this approach retains the natural hand and flow of the cotton while ensuring crisp construction. Furthermore, lightweight interlining allows for easier ironing and pressing, and reduces wrinkling or distortion after wear or washing — a key benefit for everyday garments that are laundered often.

- Ideal for summer dresses, cotton shirts, blouses — where comfort and breathability matter.

- Gives structure to edges (collars, cuffs, hems) without stiffening the whole garment.

- Maintains softness and drape of cotton while enhancing durability.

- Reduces puckering or distortion after washing.

Adhesive Interlining Fabric for Knit Fabrics (Stretch Friendly)

For garments made from stretch fabrics or knits — such as jersey knits, ponte, or stretch blends — using an adhesive interlining must be approached carefully. A specialized adhesive interlining fabric for knit fabrics stretch friendly can provide support and shape retention without impeding stretch or causing stiffness. Such interlining typically uses a more flexible adhesive layer and a lighter substrate that moves with the fabric, preserving comfort and elasticity. This is particularly important for fitted garments like knit dresses or tops, where a rigid interlining would restrict movement or distort the knit structure. When chosen and applied correctly, stretch‑friendly interlining allows clean finishing of necklines, hems, and structural seams while maintaining the comfort and flexibility inherent to knit garments.

- Maintains elasticity and drape in stretch garments, preventing restriction.

- Provides subtle structure for necklines, hems, and seam finishes without bulk.

- Ideal for fitted knit dresses, tops, stretch skirts — where comfort and fit matter.

- Helps maintain shape after multiple wears and washes without losing stretch quality.

Choosing Adhesive Interlining Fabric for Dress Shirts & Tailored Garments

For structured garments like dress shirts, blazers, or tailored garments, selecting the right adhesive interlining is crucial for achieving professional results. Using a guideline such as how to choose adhesive interlining fabric for dress shirts, one should focus on factors like weight, adhesion strength, weave tightness, and compatibility with outer fabric. A well-chosen interlining helps maintain collar stiffness, front placket crispness, and overall garment durability. For heavier fabrics used in blazers or suits, a medium-to-heavy fusible interlining might be appropriate. For dress shirts, a lighter fusible interlining gives definition without making the fabric too rigid. Proper interlining ensures collars stay erect, seams stay flat, and garments retain their form after repeated laundering or pressing.

- Enhances collar stiffness and placket crispness, giving shirts a professional look.

- Supports seams and structure in tailored garments without adding excessive bulk.

- Helps garments maintain shape over time, even with frequent wear and washing.

- Improves durability of seams and edges, reducing stretching or sagging.

How to Choose the Right Adhesive Interlining Fabric — A Decision Framework

Factors to Consider: Fabric Type, Weight, Adhesion Strength

Selecting the right adhesive interlining fabric requires evaluating multiple variables. Key among these are the type of outer fabric, the desired drape or structure, the weight of the interlining, and how strong the adhesive bond should be. For lighter fabrics (like cotton shirting or chiffon), light fusible interlining ensures the garment remains soft and breathable. Medium-to-heavy fabrics (like suit cloth or denim) may need a heavier fusible interlining to provide enough support. Adhesion strength impacts durability: a stronger bond ensures interfacing stays attached through washes and wear, but can make removal or alteration harder. Conversely, a lighter adhesive bond might offer more flexibility but less longevity. Therefore, balancing these factors is critical: the interlining must complement the garment’s purpose without compromising comfort, durability, or look.

- Outer fabric type — lightweight cotton, knit, heavy wool, etc.

- Desired drape — soft and flowing vs structured and stiff.

- Interlining weight — light, medium, or heavy fusible interlining.

- Adhesive strength — strong heat-bond vs light bond for easy removability.

- Future maintenance — ability to withstand washing, ironing, or dry cleaning.

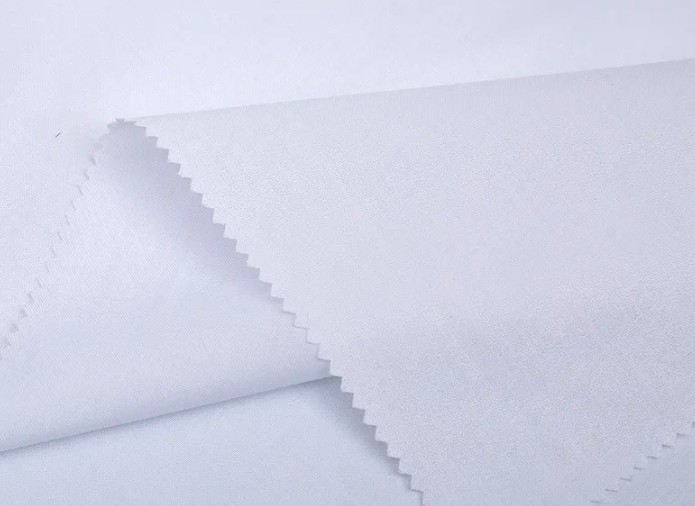

Fusible Adhesive Interlining Fabric Roll Wholesale — What to Look For

For those sourcing materials in bulk — for small factories, tailoring studios, or large-scale garment production — choosing a good-quality fusible adhesive interlining fabric roll wholesale is important to ensure consistency, cost-efficiency, and reliability. When buying wholesale rolls, one should check roll width, weight per square meter (gsm), adhesive uniformity, and ease of handling. Consistent adhesive spread ensures even bonding across all pieces. Quality inspection should confirm the adhesive layer doesn’t clump or crack, and that the substrate fabric lies flat without wrinkles. Moreover, roll format should match production needs: wide enough for pattern layouts, but manageable for ironing presses. Evaluating these wholesale rolls carefully can prevent production delays, reduce waste, and ensure all garments meet quality standards.

- Roll width — suitable for pattern layouts and fabric widths.

- Weight per square meter — ensures appropriate support for intended garments.

- Adhesive uniformity — even fusion without weak spots or clumping.

- Substrate quality — smooth, wrinkle-free, and stable under heat.

- Ease of handling — manageable roll weight and compatibility with pressing equipment.

Washable / Heat‑Bond Adhesive Interlining Fabric — Durability & Care

When longevity matters, selecting a washable heat bond adhesive interlining fabric review–grade interlining can make a difference. Heat‑bond adhesive interlining is designed to withstand repeated ironing, washing, or even dry cleaning, making it suitable for daily‑wear garments. The durability of the bond ensures that collars, hems, and seams remain crisp and stable over time. However, not all adhesive interlining performs equally — lower‑quality adhesive may degrade, separate from the fabric, or cause stiffness or puckering after washes. Therefore, when evaluating interlining, one should test through several wash‑dry cycles or simulate pressing conditions to assess longevity. Choosing washable, heat‑bond quality ensures final garments maintain structure and appearance even after repeated use and maintenance.

- Resists separation after multiple washes or dry cleaning cycles.

- Maintains adhesive integrity under repeated ironing / pressing.

- Prevents stiffness or puckering after laundering.

- Ensures long-term durability for everyday garments.

- Preserves comfort and drape despite structural support.

Application Best Practices — From Preparation to Pressing

Pre‑application Checks: Fabric Testing & Compatibility

Before committing to fusing a large batch of garments, it’s crucial to conduct compatibility tests. First, test a swatch of your outer fabric with a sample of the adhesive interlining under the recommended heat and pressure settings. This ensures the bond will hold and the fabric won’t scorch or distort. Examine the result: press crispness, flexibility, potential discoloration, and how the fabric moves. It’s also wise to test wash behavior — some adhesives may shrink or crack after washing. By doing these preliminary tests, designers and manufacturers can avoid costly errors down the line and ensure that the final garment meets quality and durability expectations.

- Test a small swatch first: fuse sample interlining to scrap fabric.

- Check adhesion: ensure uniform bond without bubbles or wrinkles.

- Assess appearance: look for discoloration or fabric distortion.

- Simulate laundering: if possible, wash/dry to test bond resilience.

- Confirm flexibility: ensure fused fabric still drapes or stretches as intended.

Step-by-Step Application for Best Results

Proper technique is essential when applying adhesive interlining. Start by cutting the interlining slightly smaller than the garment piece to avoid glue seepage at edges. Place the adhesive side down onto the wrong side of the fabric, align properly, and use a pressing cloth if needed. Apply a dry heat press or iron with recommended temperature and pressure, hold for the prescribed duration, then allow cooling before handling to ensure the adhesive sets properly. After pressing, check the bond across the entire surface — edges should lie flat, with no bubbling or lifting. If necessary, press again in areas with weak adhesion. This methodical approach ensures a clean finish, strong bond and avoids unsightly defects or weak spots in the garment.

- Trim interlining slightly smaller than fabric piece to prevent edge glue seepage.

- Place adhesive side down — align carefully before pressing.

- Use pressing cloth if fabric is delicate or shiny.

- Apply correct heat and pressure for required duration.

- Allow cooling before handling — ensures adhesive fully bonds.

- Inspect entire surface — re‑press any weak sections immediately.

Common Mistakes & How to Avoid Them

Despite its convenience, misuse of adhesive interlining can lead to problems: puckering, uneven bond, stiffness, or fabric damage. Common mistakes include applying too much adhesive, using incorrect heat settings, failing to pre‑test, cutting the interlining too large (leading to visible glue edges), or neglecting post‑press cooling. To avoid these pitfalls, always follow the interlining manufacturer’s recommended settings (or your own tested parameters), pre‑test on scraps, cut precisely, and press methodically. Being attentive to detail during application will pay off in consistent quality and longevity of the finished garment.

- Avoid over‑heating — can scorch or discolor fabric.

- Don’t skip pre‑testing — ensures compatibility.

- Cut interlining slightly smaller to prevent glue seepage.

- Use pressing cloth for sensitive fabrics.

- Allow cooling before handling — prevents premature lifting.

- Inspect thoroughly — re‑press weak spots before final assembly.

Maintenance, Washing, and Longevity of Finished Garments

Once garments are constructed using adhesive interlining, proper care is essential to maintain their structure and appearance. Heat‑bonded interlining — especially if of good quality — should withstand regular washing, ironing, or dry cleaning. However, laundering conditions matter: overly high washing temperatures or aggressive tumbling may weaken the adhesive bond over time. It’s advisable to follow gentle washing settings, use low‑heat ironing, and avoid prolonged high heat or steam pressing. Regular inspection after washing can catch early signs of separation. With proper care, garments built with adhesive interlining can maintain their crispness, shape, and durability for multiple seasons.

- Prefer gentle washing cycles or hand wash for delicate garments.

- Use low to medium heat for ironing; avoid prolonged high-heat pressing.

- Check seams, collars, hems after washing for any signs of separation.

- If separation appears early — consider re‑pressing or restringing interlining before next wash.

- Store garments properly — avoid folding heavily at interfaced areas to prevent stress on bonds.

FAQ

What is the difference between adhesive interlining and sew-in interfacing?

The primary difference lies in application method and convenience. Adhesive interlining uses a fusible glue layer that bonds to the main fabric through heat and pressure. This allows for quicker production without stitching. Sew‑in interfacing, by contrast, requires manual or machine stitching to attach to garment pieces. While sew‑in provides flexibility and easy removability, it often adds bulk and takes more time. For modern garment production, especially when speed and consistency matter, adhesive interlining tends to be preferred. In addition, adhesive interlining offers more uniform adhesion across all pieces, improving consistency and reducing variability in final product quality.

Can adhesive interlining be used on stretch knit fabrics without restricting elasticity?

Yes — provided you choose a proper adhesive interlining fabric for knit fabrics stretch friendly and apply it correctly. Knit‑friendly interlining uses a flexible substrate and lighter adhesive that won’t hinder fabric stretch. However, it remains critical to run a compatibility test before committing to full application. By doing so, you can ensure that elasticity, drape, and comfort are preserved even after fusing. If applied improperly (for example, using a heavy, rigid interlining), the bond may restrict stretch or cause distortion. Therefore, always test on scrap knit fabric under intended pressing conditions to confirm elasticity and appearance are maintained.

How do I know if fusible interlining will survive laundering and ironing over time?

The durability of a fusible interlining depends on adhesive quality, substrate stability, and correct application. To ensure longevity, select a high‑quality washable heat bond adhesive interlining fabric and perform a wash‑dry‑iron test on a swatch before full production. Observe whether the bond stays intact after multiple cycles, and whether the fabric shows signs of puckering, separation, or stiffness. Also, adhere strictly to care recommendations (gentle wash, low/medium ironing heat, avoid excessive steam). If the swatch remains stable under these conditions, the interlining is likely to perform well in finished garments. Otherwise, consider selecting a different interlining or adjusting pressing/washing procedures.

Is it more economical to buy adhesive interlining in bulk rolls for production?

For studios, small manufacturers or anyone producing multiple garments, purchasing a fusible adhesive interlining fabric roll wholesale can be more cost‑effective. Bulk rolls reduce per‑meter cost, ensure consistency across batches, and minimize waste caused by small scraps. However, savings only materialize if you ensure roll quality — uniform adhesive application, correct gsm, and manageable roll size. Poor roll quality can lead to production defects, wasted material, or inconsistent garment quality. Therefore, bulk buying makes sense only when quality standards are met and handling/pressing setup is suitable for roll format.

Contact Us for More Details

Don't hesitate to contact when you need us!

English

English  中文简体

中文简体