Revealing Thick Interlining Fabric: Key Materials for Strengthening Textile Performance

2025-07-03

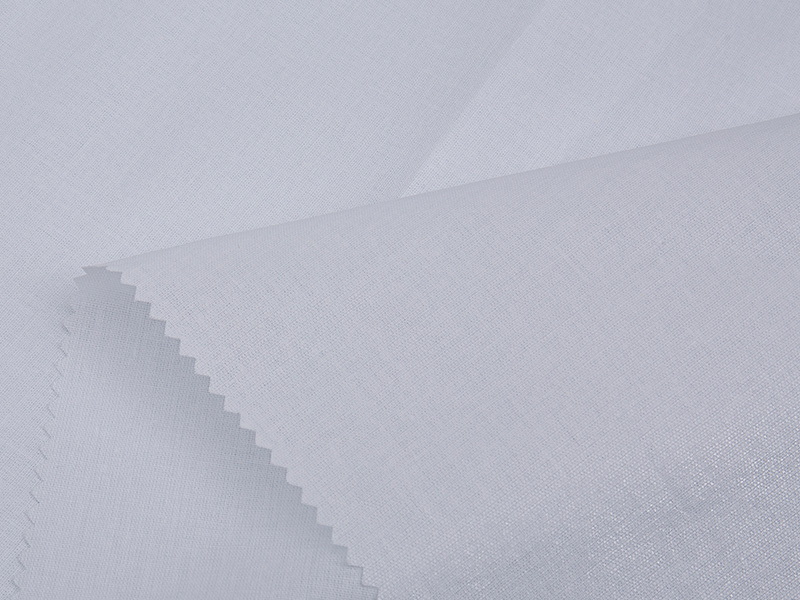

As an indispensable auxiliary material in the textile field, the core value of thick interlining fabric lies in strengthening the structural stability and shape retention of clothing, household items and various textiles. Different from ordinary interlining fabrics, thick interlining fabric is characterized by "thickness" and "strength". Through the scientific proportion of cotton, linen, polyester fibers and their blended materials, a solid physical structure foundation is built. This material selection is not a simple stacking, but is based on the precise control of the mechanical properties of the fiber.

Multi-dimensional analysis of performance advantages

The performance of thick interlining fabric is reflected in the all-round optimization of textile contour shaping, support performance enhancement and durability improvement. In terms of contour shaping, its thickness characteristics can provide a three-dimensional base for the fabric. Whether it is the crisp lines of the shoulders of a suit or the fluffy shape of the skirt, thick interlining fabric can transform the design concept into a stable three-dimensional form through precise shaping ability. In terms of supporting performance, high-strength fiber materials give thick interlining fabric strong anti-deformation ability. Even if it is subjected to frequent pulling or long-term pressure, it can still maintain structural integrity and effectively avoid the collapse or deformation of textiles caused by external forces. In terms of durability, thick interlining fabric relies on the properties of the material and special processing technology to significantly improve the wear and aging resistance of the finished product, extend the life cycle of textiles, and reduce maintenance costs and replacement frequency.

Multi-field application scenario analysis

Thick interlining fabric shows strong adaptability and functionality in textile application scenarios. In the field of clothing manufacturing, it is the core material for the lining of formal suits such as suits and coats. By enhancing the stiffness of the fabric, it improves the overall texture and wearing comfort of the clothing; when used in the production of skirts, it can support a full and layered skirt shape to meet the needs of different styles of design. In the field of household goods, thick interlining fabric also plays an important role: using thick interlining fabric as a supporting structure inside sofa cushions can enhance the support force, optimize the sitting and lying experience and keep the sofa appearance flat; in curtain production, thick interlining fabric can give the fabric a sense of drape and three-dimensionality, and enhance the overall aesthetics of home decoration. In the production of heavy home textile products such as carpets and bedspreads, thick interlining fabric, with its high strength characteristics, provides reliable internal support for these textiles that carry heavy objects or need to be used frequently, ensuring the stability of the structure.

Process technology and quality assurance system

The stable performance of thick interlining fabric depends on advanced production technology and strict quality control system. In the raw material processing link, the material performance is optimized by precisely controlling the fiber ratio and pretreatment process; in the weaving process, special textile technology is used to achieve a close and orderly arrangement of fibers to form a high-strength fabric structure; the post-finishing process uses shaping, coating and other processes to further improve the stability and functionality of thick interlining fabric. At the same time, the complete quality inspection process runs through the entire production cycle, from the strict testing of key indicators such as thickness uniformity, tensile strength to weather resistance, to ensure that each batch of products can meet high standards and provide reliable guarantees for downstream applications.

Innovation path under the trend of sustainable development

Facing the trend of the textile industry's transformation towards green and sustainable development, thick interlining fabric is also actively exploring innovative development models. On the one hand, the R&D team is committed to developing environmentally friendly fiber materials, reducing the impact of products on the environment by using degradable fibers or recycled materials; on the other hand, optimizing production processes, reducing energy consumption and pollutant emissions, and achieving clean production. Through technological innovation, the versatility of thick interlining fabric is enhanced, such as the development of composite products with both warmth and antibacterial properties. While meeting the needs of structural strengthening, it expands its application boundaries and promotes thick interlining fabric to play a greater role in the sustainable development process of the textile industry.

Contact Us for More Details

Don't hesitate to contact when you need us!

English

English  中文简体

中文简体