Shirts Interlining: The Invisible Key to Improving Clothing Quality

2025-07-10

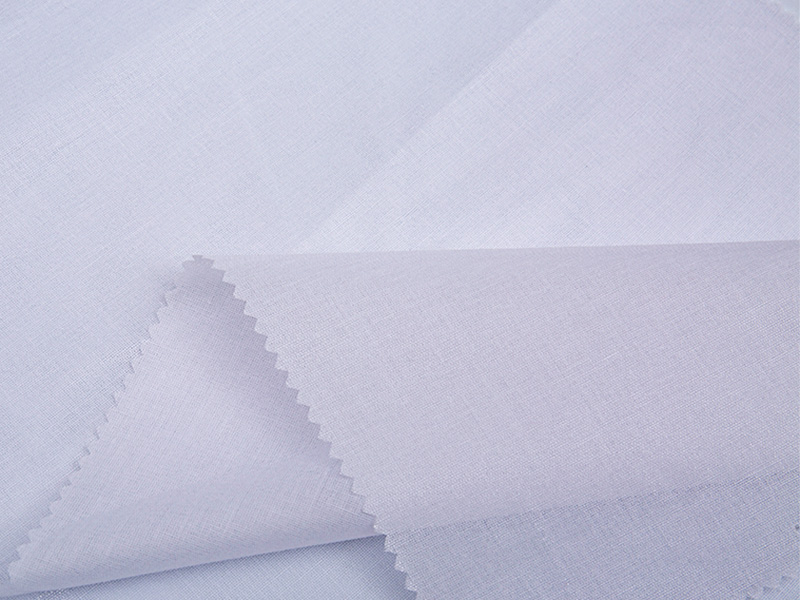

As an indispensable component of the clothing accessories system, shirts interlining is a functional lining designed specifically for shirts. Its core value lies in building the three-dimensional structure of the shirt. Through scientific material selection and process design, it gives the clothing a long-lasting and crisp shape, comfortable and skin-friendly wearing feel, and stable durability without destroying the original texture of the fabric. This seemingly invisible material is actually a key factor in improving the quality of shirts, and runs through the entire life cycle from plate making and cutting to daily wear.

Reshaping the three-dimensional shape of shirts

During the wearing process, shirts need to withstand frequent body movements and external friction, which are prone to problems such as neckline deformation and placket wrinkling. Interlining builds a stable mechanical support system for shirts by enhancing the wrinkle resistance and structural strength of the fabric. In key parts such as the neckline, cuffs and placket, the interlining transforms the flat fabric into a three-dimensional shape through the precise fitting of the cutting pieces, so that the neckline remains upright and crisp, the cuffs remain flat during repeated opening and closing, and the placket lines are always smooth and natural. This structural support not only improves the appearance and texture of clothing, but also reduces the accumulation of wrinkles caused by fabric loosening, reducing the wearer's care costs.

Ergonomic considerations of material technology

The comfort of high-quality shirts interlining comes from the dual control of materials and craftsmanship. The selection of natural fibers such as pure cotton and modal can ensure that the interlining has good skin-friendliness and moisture absorption, avoiding the stuffiness that may be caused by chemical fiber materials; and the blending technology of polyester fiber and natural fiber improves the strength and wrinkle resistance of the fabric while maintaining breathability. The application of special functional fibers such as cool fibers and antibacterial fibers enables the interlining to actively adjust the wearing feel to meet the functional needs of different scenarios. The precise weaving process ensures that the thickness of the interlining is controlled between 0.1-0.3 mm, which not only provides necessary support but also remains light and soft, perfectly blending with the shirt fabric to avoid the feeling of wearing foreign objects.

The art of balancing aesthetics and functionality

The visual optimization effect of interlining is reflected in two dimensions: first, it prevents the flesh from showing through by increasing the density of the fabric, which is particularly critical in light-colored shirts or thin and transparent fabrics; second, it reduces the uneven reflection of the fabric by smoothing the surface of the interlining, so that the clothing presents a uniform and soft glossy texture. For easily deformed fabrics such as silk and chiffon, the interlining can be adjusted by warp and weft tension to avoid curling of the cutting edge, ensure accurate alignment of the cut pieces, and improve the overall sewing accuracy. This visual optimization is not a simple material superposition, but a balance between functionality and aesthetics through the synergy of material mechanics and optical principles.

Technical guarantee for extending the life cycle of clothing

shirts interlining improves the durability of clothing through the dual mechanisms of physical protection and chemical treatment. In areas prone to wear, the interlining reduces pilling and breakage caused by friction by enhancing the bonding force between fabric fibers; and the interlining with functional finishing such as antistatic and antifouling can reduce dust adsorption and stain penetration, extending the wearing cycle of the shirt. The interlining fabric treated with special technology also has a memory function. It can still restore its original shape after multiple washings, effectively preventing common problems such as neckline deformation and cuff loosening, so that the shirt can maintain its appearance for a long time.

Technological evolution from traditional to intelligent

The production of modern shirts interlining has formed a systematic process system. From traditional hot melt bonding to digital cutting design, the technological iteration has significantly improved product performance. Laser cutting technology can achieve 0.1 mm precision control to ensure seamless fit between the interlining fabric and the fabric; the intelligent temperature control bonding process can accurately control the temperature, pressure and time parameters to form a stable combination between the interlining fabric and the fabric without damaging the fiber structure. The application of new environmentally friendly adhesives can reduce the residual harmful substances such as formaldehyde while ensuring the bonding strength, which meets the modern consumers' pursuit of healthy and environmentally friendly quality. With its precise functional design and material innovation, shirts interlining has built a dual optimization system for clothing structure and wearing experience. From the fiber selection at the micro level to the three-dimensional modeling at the macro level, every detail reflects the deep integration of material science and clothing engineering.

Contact Us for More Details

Don't hesitate to contact when you need us!

English

English  中文简体

中文简体