Your Ultimate Guide to Interfacing Fabric: Types, Applications, and Innovations

2026-01-28

In the intricate world of textiles and garment construction, the unseen hero that provides structure, shape, and durability is interfacing fabric. Often hidden between layers of fabric, this essential material is the foundation upon which professional-quality apparel and durable textile products are built. For over two decades, Hetai Textile has been at the forefront of this specialized field, evolving from a focused manufacturer into a full-spectrum enterprise dedicated to the development, production, and innovation of high-quality interlining solutions. Based in Jiangsu Province, China, our integrated facilities—encompassing weaving, dyeing, and coating—are powered by advanced technology and a skilled technical team committed to pushing the boundaries of quality and performance.

What is Interfacing Fabric?

Interfacing fabric, commonly referred to as interlining, is a supportive material applied to the wrong side of fabrics to add body, stability, and shape. It is a critical component in achieving a polished look in tailored garments, structured bags, and various textile applications.

Core Functions and Benefits

- Provides Structure & Shape: Prevents fabrics from stretching out of form, essential for collars, cuffs, and waistbands.

- Adds Body & Fullness: Gives lightweight fabrics more substance and a luxurious drape.

- Enhances Durability: Reinforces areas of stress, such as buttonholes and pockets, extending the garment's lifespan.

- Improves Professional Finish: Creates crisp edges and smooth silhouettes, distinguishing handmade or manufactured items.

Five Essential Types of Interfacing Fabric Explained

Choosing the correct interfacing is paramount to a project's success. The choice often hinges on the base fabric's weight and the desired effect.

1. Woven vs. Non-Woven Interfacing

This fundamental distinction refers to the internal structure of the interfacing material itself.

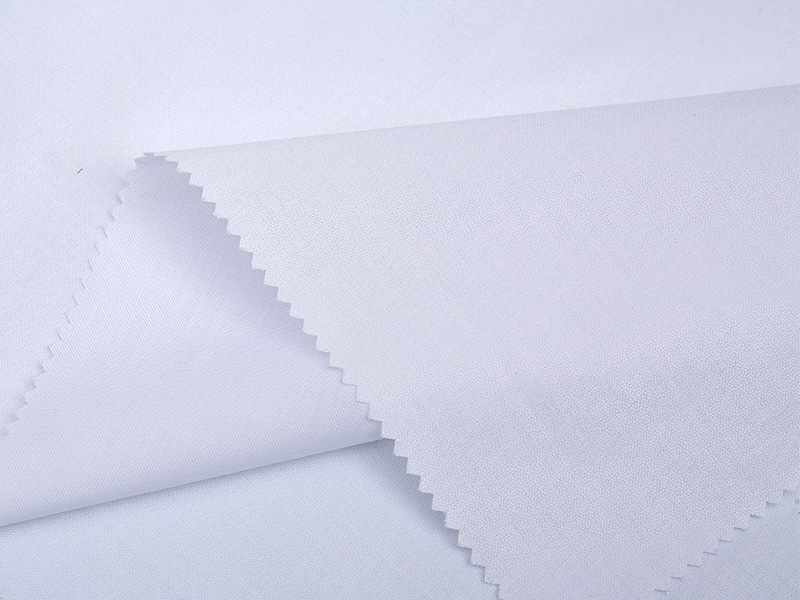

Woven interfacing has threads running in lengthwise (warp) and crosswise (weft) directions, similar to standard fabrics. This structure provides stability with a degree of natural flexibility, making it ideal for tailored garments where durability and a natural drape are needed. In contrast, non-woven interfacing is made from fibers bonded together through mechanical, chemical, or heat processes. It has no grain line, making it easy to cut in any direction, but it can be less durable and more prone to wrinkling than its woven counterpart.

| Aspect | Woven Interfacing | Non-Woven Interfacing |

|---|---|---|

| Structure | Constructed with warp and weft threads. | Fibers bonded together; no grain. |

| Drapability | Generally more flexible and natural. | Can be stiffer; drape varies by weight. |

| Durability | Typically more durable and resilient. | May tear more easily; less durable for high-stress areas. |

| Best For | Tailoring, wool garments, structured bags. | Crafts, medium-weight apparel, temporary shaping. |

For projects requiring a balance of structure and natural movement, such as a suit jacket's chest piece, woven fusible interfacing for heavy fabrics is often the professional's choice.

2. Fusible vs. Sew-In Interfacing

This classification is based on the application method.

Fusible interfacing has a heat-activated adhesive on one side, which is ironed onto the fabric. It is quick to apply and provides a very stable bond, excellent for preventing fabric layers from shifting. Sew-in interfacing, as the name implies, is basted or sewn by hand or machine to the fabric. It offers a softer, more flexible result and is essential for fabrics that cannot withstand the heat of an iron, such as silks, sequined fabrics, or certain synthetics.

| Aspect | Fusible Interfacing | Sew-In Interfacing |

|---|---|---|

| Application | Ironed on using heat and pressure. | Sewn onto the fabric. |

| Result | Crisp, very stable bond; can stiffen hand feel. | Softer, more fluid hand feel; less rigidity. |

| Fabric Compatibility | Not suitable for heat-sensitive fabrics. | Ideal for delicate, textured, or heat-sensitive fabrics. |

| Best For | Shirt collars, quilting, home decor projects. | Sheer fabrics, knits, luxury materials like velvet. |

When working with delicate materials, understanding how to choose interfacing for delicate fabrics is crucial, often leading to the selection of a lightweight sew-in variant.

3. Knit Interfacing for Stretch Fabrics

A specialized category designed specifically for jersey, sweater knits, and other stretch materials.

- Inherent Flexibility: Knit interfacing itself has a degree of stretch, allowing it to move with the base fabric without restricting elasticity or causing bubbling.

- Prevents Deformation: It stabilizes areas like necklines and shoulder seams without creating undesirable stiffness, which is a common pitfall when using non-stretch interfacing on knits.

- Application: Available in both fusible and sew-in forms, with fusible knit interfacing being particularly popular for its ease of use.

This makes it the definitive solution for best interfacing for knit clothing, ensuring the finished garment retains its comfort and fit.

4. Specialized Interfacing Types

Beyond the basic categories, advanced interfacing solutions address specific needs.

Hair Canvas

Considered the gold standard for traditional tailoring. A combination of animal hair (goat, horse) and wool, it is primarily sew-in and provides a resilient, moldable structure that shapes to the body over time.

Welt or Cutaway Interfacing

Extremely stable and non-fraying, used in machine embroidery to stabilize the fabric during dense stitching. It is often "cut away" from the back after embroidery is complete.

Fusible Fleece

Provides not only stability but also light loft and warmth, making it perfect for quilted bags, jackets, and home decor items like placemats.

How to Select the Right Interfacing: A Professional's Checklist

Selecting the wrong interfacing can ruin a project. Follow this systematic approach to ensure perfect results every time.

Step 1: Analyze Your Main Fabric

- Weight & Drape: The interfacing should generally match or be slightly lighter than the main fabric's weight.

- Fiber Content: Consider heat sensitivity (for fusibles) and care instructions (dry clean only vs. washable).

- Texture: Test fusibles on a scrap to ensure the adhesive doesn't bleed through or alter the fabric's surface.

Step 2: Define the Desired Effect

- Do you need crisp rigidity (e.g., a shirt collar) or soft support (e.g., a jacket lapel)?

- Should the interfacing add body without weight, or is substantial structure required?

This decision-making process is at the heart of mastering interfacing fabric weight guide for sewing.

Step 3: Consider the Application Method

- Will the fabric tolerate heat and steam?

- Is the project time-sensitive (favoring fusible) or focused on the highest quality hand (favoring sew-in)?

Step 4: Test, Test, Test

Always conduct a test on a fabric scrap. Check for changes in color, texture, drape, and the bond's strength after washing or cleaning. This practice is indispensable for achieving sewing tips for perfect interfacing results.

The Role of Innovation in Modern Interlining Production

The industry has moved far beyond basic stiffening materials. At Hetai Textile, innovation is embedded in our process. Our integrated weaving, dyeing, and coating workshops allow for precise control at every stage.

Material Science Advances

- Low-Temperature Fusibles: Developed for heat-sensitive synthetic fabrics and modern lightweight materials.

- Eco-Conscious Formulations: Research into bio-based adhesives and recycled fiber content to reduce environmental impact.

- Enhanced Performance: Interfacings with moisture-wicking properties, breathability, or wash-out features for temporary support.

Precision Manufacturing

Our advanced production lines and technical team enable us to produce interfacing with exceptional consistency in weight, adhesive distribution, and shrinkage control. This level of precision ensures that our products meet the exacting standards of diverse global markets, from high fashion to functional workwear, effectively serving interfacing for bags and accessories tutorial needs that demand both durability and aesthetics.

FAQs About Interfacing Fabric

1. Can I substitute one type of interfacing for another?

It is not generally recommended. The different types (woven/non-woven, fusible/sew-in) are engineered for specific purposes. Substituting can lead to poor drape, bubbling, or inadequate support. Always try to use the type specified in your pattern or chosen based on your fabric analysis.

2. Why did my fusible interfacing bubble or peel after washing?

This is usually caused by one of three issues: insufficient heat or pressure during application, using a fusible incompatible with the fabric's care instructions (e.g., a non-washable interfacing on a washable fabric), or an inherent quality issue with the interfacing's adhesive. Pre-washing both fabric and interfacing and thorough testing can prevent this.

3. How do I apply fusible interfacing correctly?

Use a press cloth to protect your iron and fabric. Apply a dry, medium-to-hot iron (suitable for the main fabric) with firm, steady pressure for 10-15 seconds per section. Do not use a sliding motion, as this can shift the interfacing. Allow the fused piece to cool completely before moving it.

4. Is there an interfacing that works for all fabrics?

No single interfacing is universally perfect. The vast range of fabric weights, fibers, and textures requires a corresponding range of interfacing solutions. This is why manufacturers like Hetai Textile produce a comprehensive portfolio to meet these varied needs.

5. How does interfacing differ from interlining or lining?

Interfacing is a stabilizer fused or sewn to specific garment parts for structure. Interlining is often used as a synonym but can also refer to an insulating layer between shell and lining. Lining is a separate fabric layer that covers the inside of a garment for aesthetics, comfort, and wearability, but does not provide primary structural support.

Mastering interfacing fabric is a cornerstone of professional textile and garment creation. From understanding the critical choice between woven and non-woven, fusible and sew-in, to selecting the best interfacing for knit clothing or following a detailed interfacing fabric weight guide for sewing, this knowledge empowers creators to achieve superior results. The field is constantly evolving, driven by material innovation and precision manufacturing from companies like Hetai Textile. With over twenty years of expertise, we are committed to providing the foundational materials that help turn creative visions into durable, beautifully finished realities. By applying the principles and sewing tips for perfect interfacing results, and leveraging specialized knowledge for interfacing for bags and accessories tutorial projects or how to choose interfacing for delicate fabrics, every maker can ensure their work stands the test of time and use.

References

[1] Shaeffer, C. (2001). *Couture Sewing Techniques*. Taunton Press. (Reference for traditional tailoring methods and use of hair canvas).

[2] Palmer, P., & Walters, S. (2012). *The Practical Guide to Patternmaking for Fashion Designers: Juniors, Misses and Women*. Fairchild Books. (Reference for foundational garment structure and interfacing applications).

[3] Textile Institute. (2020). *Textile Terms and Definitions*. Textile Institute. (Reference for standardized definitions of woven, non-woven, and interlining).

Contact Us for More Details

Don't hesitate to contact when you need us!

English

English  中文简体

中文简体